- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Application of PCBA processing in medical equipment

2024-12-12

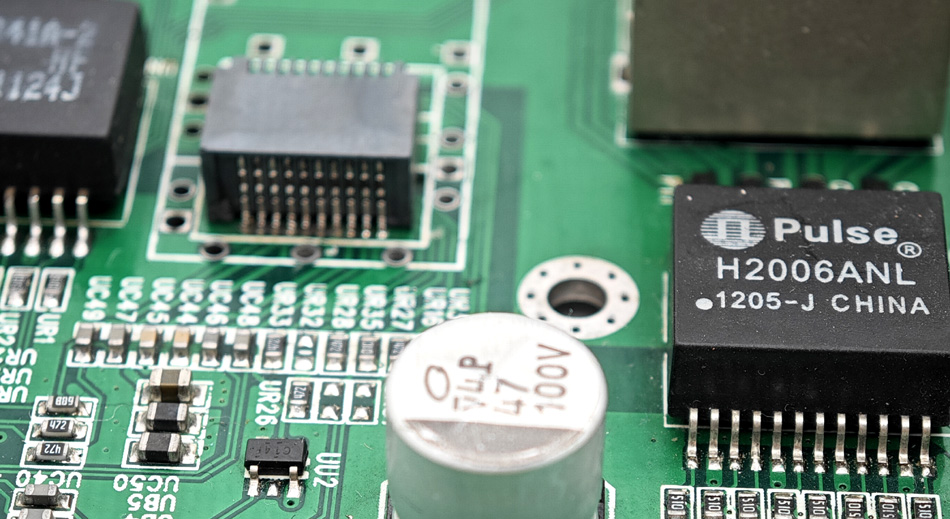

With the continuous advancement of science and technology and the development of the medical industry, PCBA processing is increasingly used in medical equipment. This article will explore the application of PCBA processing in medical equipment and introduce its importance and role in the medical field.

1. Overview of PCBA processing in medical equipment

Medical equipment involves multiple fields such as diagnosis, treatment, and monitoring. Most of these devices require the support of electronic control systems, and PCBA (Printed Circuit Board Assembly) processing is one of the core components of electronic control systems. PCBA processing achieves the functionality and stability of electronic equipment by installing components and connecting lines on circuit boards.

2. Common PCBA processing applications in medical equipment

2.1 Medical imaging equipment

Medical imaging equipment such as X-ray machines, CT scanners, MRI, etc., all require PCBA processing to realize image acquisition, processing and display, ensuring that doctors can accurately diagnose and treat diseases.

2.2 Medical monitoring equipment

Medical monitoring equipment such as electrocardiographs, blood pressure monitors, ventilators, etc., require PCBA processing to realize data acquisition, transmission and monitoring to ensure the safety and health of patients.

2.3 Treatment equipment

Medical treatment equipment such as surgical robots, laser therapy devices, and electrical stimulators rely on PCBA processing to achieve precise control and treatment effects, and improve treatment accuracy and safety.

2.4 Laboratory equipment

Laboratory equipment such as biochemical analyzers, PCR instruments, centrifuges, etc. require PCBA processing to achieve data collection, analysis, and control to support scientific research and clinical diagnosis.

3. The importance of PCBA processing in medical equipment

3.1 Stability and reliability

Medical equipment has very high requirements for stability and reliability. The accuracy and quality control of PCBA processing are directly related to the operating stability and data accuracy of the equipment.

3.2 Functionality and flexibility

PCBA processing can be customized according to the functional requirements of medical equipment, meet the functional and flexibility requirements of different equipment, and provide personalized solutions.

3.3 Data security and privacy protection

Medical equipment involves sensitive data and privacy information of patients. PCBA processing needs to ensure data security and privacy protection to prevent data leakage and information damage.

4. Future development of PCBA processing in medical equipment

With the continuous advancement of medical technology and the intelligent development of medical equipment, the application of PCBA processing in medical equipment will be more extensive and in-depth. In the future, PCBA processing will pay more attention to technological innovation and intelligent design to improve the performance and user experience of medical equipment.

Conclusion

PCBA processing plays an important role in medical equipment and provides reliable technical support for the development of the medical industry and the health of patients. Medical equipment manufacturers should focus on quality control and technological innovation of PCBA processing, improve the quality and competitiveness of medical equipment, and contribute to the sustainable development of the medical industry.

-

Delivery Service

-

Payment Options