- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

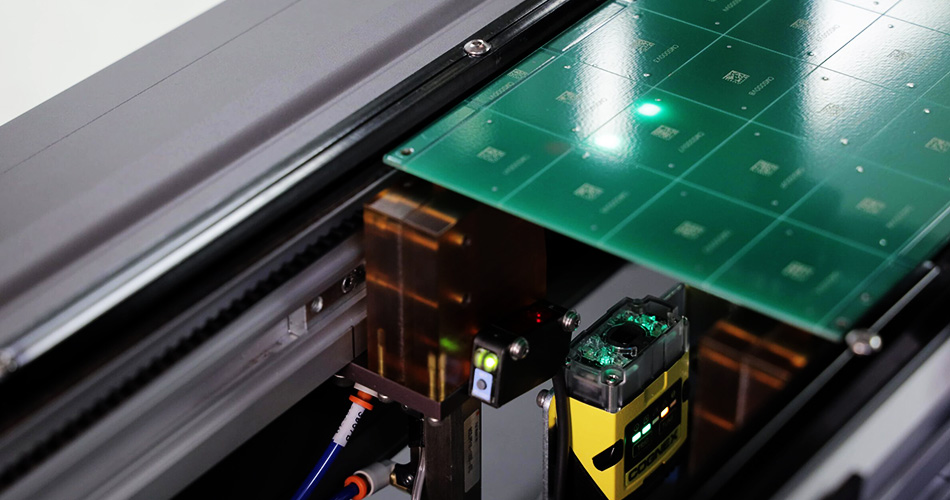

Application of automation equipment in PCBA processing

2024-12-18

With the continuous advancement of science and technology and the intelligent development of manufacturing industry, automation equipment plays an increasingly important role in the field of PCBA processing. This article will explore the application of automation equipment in PCBA processing, including definitions, key technologies and advantages.

1. Definition of automation equipment in PCBA processing

Automation equipment refers to equipment that uses advanced technologies such as computers, machinery, and electronic technology to automatically control and operate the production process. In PCBA processing, automation equipment mainly includes automatic placement machines, automatic soldering machines, automatic testing equipment, etc.

2. Application fields of automation equipment

2.1 Automatic placement machine

Automatic placement machines can realize automatic placement of electronic components, including patch components, IC chips, connectors, etc. Through high-speed and precise patch operations, the installation efficiency and accuracy of components are improved, and the errors and costs of manual operations are reduced.

2.2 Automatic soldering machine

Automatic soldering machines are mainly used for the soldering process of PCB boards, including surface mount technology (SMT) and Through Hole Technology (THT). Automatic soldering machines can realize automatic heating, soldering and cooling of solder points, ensure soldering quality and stability, and improve production efficiency and product quality.

2.3 Automatic detection equipment

Automatic detection equipment is mainly used for automated detection and testing of PCB boards and components, including electrical testing, functional testing, AOI (automatic optical inspection), etc. The application of automatic detection equipment can improve product quality control and production efficiency.

3. Key technologies of automation equipment

3.1 Mechanical structure design

The mechanical structure design of automation equipment needs to consider factors such as working stability, load capacity, and precision requirements, and adopt advanced mechanical design and manufacturing technology to ensure the reliability and performance optimization of the equipment.

3.2 Control system

The control system of automation equipment is the core of realizing equipment automation operation and intelligent management, including PLC control, motion control, human-machine interface and other technologies to ensure stable operation and efficient production of equipment.

3.3 Data acquisition and analysis

Use sensors and data acquisition systems to collect key parameters and data in the production process in real time, and improve the operation efficiency and production quality of equipment through data analysis and optimization algorithms.

4. Advantages of Automation Equipment Application

4.1 Improve Production Efficiency

Automation equipment can realize automated operation and high-speed production of the production process, improve production efficiency and capacity, and shorten the production cycle.

4.2 Reduce production costs

Automation equipment reduces manual operation and errors, reduces production costs and labor costs, and improves production benefits and competitiveness.

4.3 Improve product quality

Automation equipment can achieve precise patch, soldering and testing, ensure product quality and stability, reduce product defect rates and quality problems, and improve customer satisfaction.

5. Development trend of automation equipment in the future

With the development of Industry 4.0 and intelligent manufacturing, automation equipment will become more intelligent and flexible, such as human-machine collaborative robots, intelligent manufacturing systems, etc., which further improves the production efficiency and quality level of PCBA processing.

Conclusion

The application of automation equipment in PCBA processing continues to expand and deepen, providing enterprises with more production advantages and competitiveness. In the future, with the continuous innovation and development of technology, automation equipment will continue to play an important role in promoting the intelligent and efficient development of the PCBA processing industry.

-

Delivery Service

-

Payment Options