- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Artificial Intelligence Application in PCBA Processing

2024-12-20

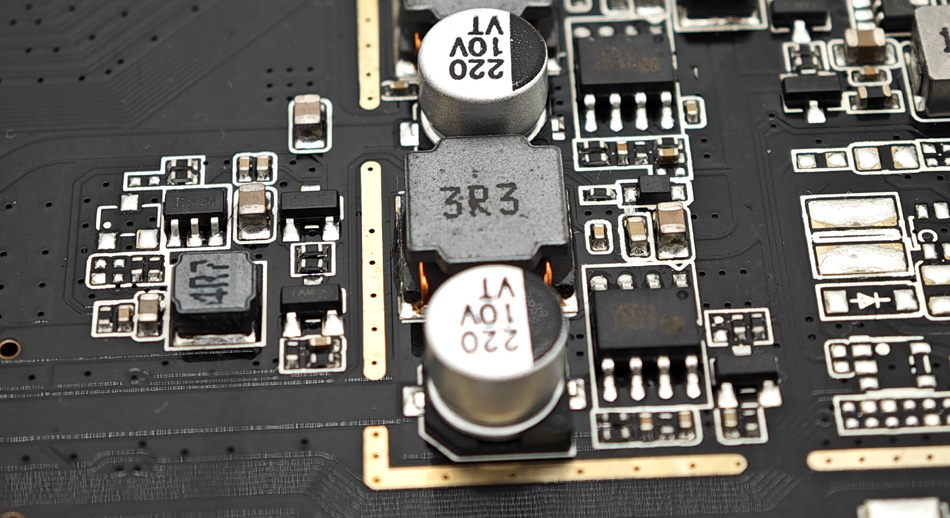

PCBA processing (Printed Circuit Board Assembly) is an important part of electronic product manufacturing, and its complexity and precision requirements are increasing day by day. The introduction of artificial intelligence (AI) has brought significant efficiency improvements and quality assurance to PCBA processing. This article will explore the application of artificial intelligence in PCBA processing, including intelligent detection, process optimization, predictive maintenance and quality control.

1. Intelligent detection

1.1 Automatic Optical Inspection (AOI)

During the PCBA processing process, automatic optical inspection equipment uses machine vision technology, combined with artificial intelligence algorithms, to quickly and accurately identify and determine problems such as solder joints, misalignment and missing components. Compared with traditional manual inspection, AOI greatly improves inspection efficiency and accuracy.

1.2 X-ray inspection (AXI)

AXI combines AI technology to perform high-precision non-destructive inspection of PCBA internals. It is especially suitable for inspecting multi-layer circuit boards and complex solder joints to ensure that there are no internal defects in the product and improve quality reliability.

2. Process optimization

2.1 Production parameter optimization

By analyzing a large amount of data during PCBA processing through artificial intelligence, the optimal production parameters can be found. AI algorithms can adjust the working status of placement machines, reflow soldering and other equipment in real time to ensure the stability and consistency of the production process.

2.2 Process automation

The AI-driven automation system can intelligently adjust the configuration and operation of the production line based on production needs and real-time data, optimize the production process, reduce human intervention, and improve overall production efficiency.

3. Predictive maintenance

3.1 Equipment status monitoring

AI technology can monitor the operating status of PCBA processing equipment in real time. By analyzing the working data of the equipment, it can predict equipment failures and maintenance needs, arrange maintenance work in advance, and avoid production stagnation caused by sudden equipment failures.

3.2 Preventive maintenance

Combining big data analysis and machine learning algorithms, AI can build equipment health models, predict equipment life and possible failure points, implement preventive maintenance, extend equipment service life, and reduce maintenance costs.

4.1 Data-driven quality management

Artificial intelligence can conduct real-time analysis and monitoring of massive data generated during PCBA processing, discover potential causes of quality problems, provide solutions, and ensure product consistency and reliability.

4.2 Defect prediction and prevention and control

Through deep learning of historical data, AI can predict possible defects during processing and conduct real-time prevention and control during the production process, reducing product defect rates and improving yield rates.

5. Application cases

An electronics manufacturing company introduced AI technology for PCBA processing and achieved remarkable results in automatic detection, process optimization and predictive maintenance. Through the intelligent detection of AOI and AXI, product quality problems have been significantly reduced; production parameter optimization and process automation have increased production efficiency by 20%; the predictive maintenance system has effectively reduced equipment failure rates and maintenance costs.

Conclusion

The application of artificial intelligence in PCBA processing has brought new development opportunities to the electronics manufacturing industry. Through intelligent detection, process optimization, predictive maintenance and quality control, AI technology has significantly improved the efficiency and quality of PCBA processing. In the future, with the continuous advancement and application of AI technology, PCBA processing will usher in greater innovations and breakthroughs, pushing the electronics manufacturing industry to a higher level.

-

Delivery Service

-

Payment Options