- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Comparison of PCBA processing and traditional manufacturing

2024-12-22

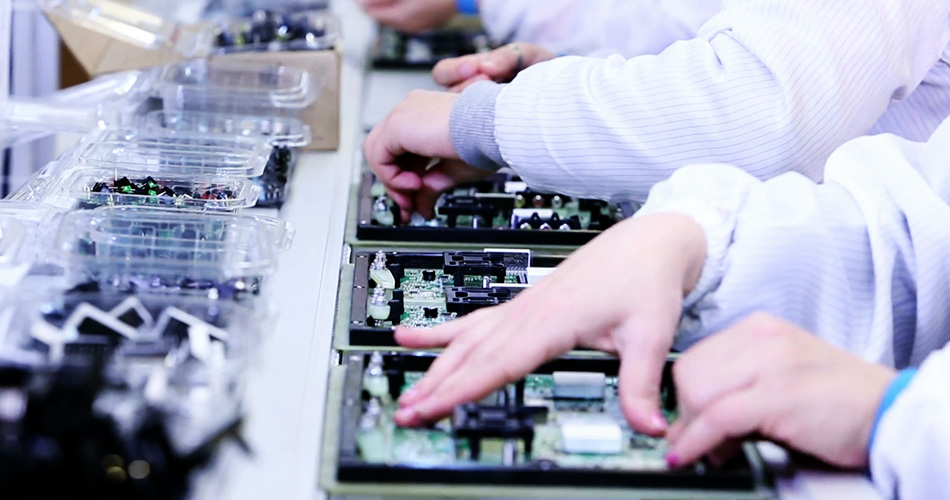

In modern manufacturing, PCBA processing (printed circuit board assembly) has gradually become a key technology. Compared with traditional manufacturing methods, PCBA processing not only improves product performance and reliability, but also significantly reduces production costs and time. This article will compare the differences between PCBA processing and traditional manufacturing in detail and explore their respective advantages and disadvantages.

1. What is PCBA processing?

PCBA processing refers to the process of assembling electronic components on a printed circuit board (PCB). The process includes various methods such as surface mount technology (SMT), through hole technology (THT) and hybrid technology. Through automated equipment and precision technology, various electronic components are installed on the PCB to form a fully functional circuit system.

2. Overview of traditional manufacturing

Traditional manufacturing mainly relies on methods such as mechanical processing, manual assembly and soldering. Although this method still plays an important role in some fields, due to its complex processes and high labor costs, it is increasingly difficult to meet the efficient and precise needs of modern electronic products.

3. Advantages of PCBA processing

3.1 High degree of automation

PCBA processing is highly dependent on automated equipment, such as placement machines, reflow ovens and wave soldering machines. These equipment can complete the installation of a large number of electronic components in a short time, greatly improving production efficiency.

3.2 Accuracy and reliability

Since PCBA processing adopts advanced manufacturing technology and strict quality control, the accuracy and reliability of the product are significantly improved. Automated equipment can accurately control the position and soldering quality of components, reducing the possibility of human error.

3.3 Cost-effectiveness

PCBA processing significantly reduces production costs by reducing labor requirements and improving production efficiency. In addition, with the advancement of technology and the popularization of equipment, the cost of PCBA processing is gradually declining.

3.4 Flexibility

PCBA processing can adapt to the design requirements of various complex circuits and has high flexibility. Whether it is small batch customized production or large-scale mass production, PCBA processing can easily handle it.

4. Disadvantages of traditional manufacturing

4.1 The process is complicated

Traditional manufacturing often requires multiple processes, which are cumbersome and inefficient. Especially for the production of complex circuits, it is difficult to guarantee quality and consistency with traditional manufacturing.

4.2 High labor costs

Traditional manufacturing relies heavily on manual operations, which not only increases production costs, but is also easily limited by personnel skills and experience, resulting in unstable product quality.

4.3 Technical limitations

As electronic products become more complex and miniaturized, traditional manufacturing methods are unable to cope with the design of high-density, miniaturized circuits. In contrast, PCBA processing can better adapt to the development needs of modern electronic products.

in conclusion

To sum up, PCBA processing has obvious advantages in modern manufacturing. A high degree of automation, precision, cost-effectiveness and flexibility make it a mainstream choice for electronics manufacturing. Although traditional manufacturing still has its value in certain specific fields, with the continuous advancement of technology, PCBA processing will surely become the dominant force in the future manufacturing industry.

By adopting PCBA processing technology, companies can not only improve production efficiency and product quality, but also occupy a favorable position in the fierce market competition. In the future, with the continuous development of PCBA processing technology, its application scope will be wider, bringing more innovation and development opportunities.

-

Delivery Service

-

Payment Options