- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

How to improve product competitiveness through PCBA processing

2024-12-24

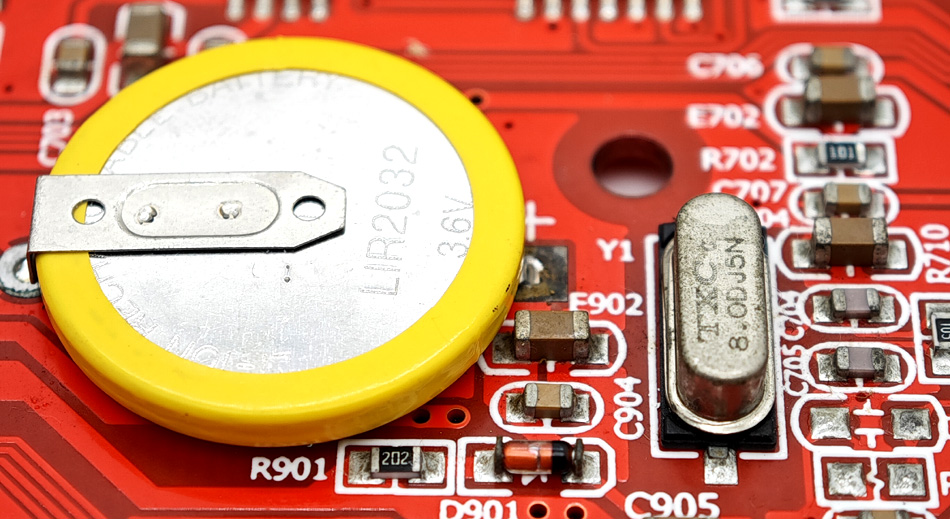

In the manufacturing process of modern electronic products, PCBA processing (Printed Circuit Board Assembly) plays a vital role. Efficient and precise PCBA processing can not only improve the quality and reliability of products, but also significantly enhance the market competitiveness of products. This article will explore specific methods and strategies to improve product competitiveness through PCBA processing.

1. The importance of PCBA processing

PCBA processing is one of the core links in electronic product manufacturing, covering everything from component selection and procurement, to soldering and assembly, to final testing and quality control. High-quality PCBA processing can ensure that products meet or exceed industry standards in terms of performance, durability and safety, thereby enhancing the market competitiveness of products.

2. Improve product performance and reliability

2.1 Choose high-quality components

In the PCBA processing process, it is crucial to choose high-quality components. High-quality components can not only improve the overall performance of the product, but also extend the service life of the product. By cooperating with well-known component suppliers to ensure that the purchased components meet strict quality standards, this is the first step to improve product competitiveness.

2.2 Advanced soldering technology

soldering technology is one of the key links in PCBA processing. The use of advanced soldering technologies, such as surface mount technology (SMT) and reflow soldering technology, can ensure that components are firmly connected to the circuit board, reduce soldering defects, and improve product reliability and stability.

3. Optimize production process

3.1 Automated production line

The introduction of automated production lines is an effective means to improve PCBA processing efficiency and quality. Automated equipment can accurately control soldering temperature and time, reduce human errors, and improve production consistency and product qualification rate. In addition, automated production lines can also significantly increase production speed to meet the needs of mass production.

3.2 Quality control system

Establishing a complete quality control system and conducting strict testing and control of each process can effectively reduce the defective rate of products. Including online testing (ICT), functional testing (FCT) and final aging testing, etc., to ensure that each PCBA can meet the expected performance and quality standards.

4. Shorten product time to market

4.1 Rapid prototyping

In the product development stage, rapid prototyping can help companies complete functional verification and performance testing of products in a short time. By cooperating with professional PCBA processing factories, prototype production can be completed quickly and the product development process can be accelerated.

4.2 Flexible production arrangements

Flexible production arrangements can quickly adjust production plans according to market demand to ensure that products can be launched on time. Especially at the critical moment of new product release and market promotion, rapid response to market changes is a key factor in improving product competitiveness.

5. Reduce production costs

5.1 Centralized purchasing

By centralizing the procurement of components, companies can obtain more competitive prices and reduce procurement costs. In addition, establishing long-term cooperative relationships with suppliers can ensure a stable supply of components and avoid production delays caused by component shortages.

5.2 Lean production

Adopting the lean production concept, optimizing the production process, reducing waste and improving production efficiency is an effective way to reduce production costs. Through lean production, resources can be utilized to the maximum extent and the overall competitiveness of the enterprise can be enhanced.

in conclusion

To sum up, by optimizing all aspects of the PCBA processing process, companies can significantly improve product performance and reliability, shorten product time to market, reduce production costs, and thus occupy a favorable position in the fierce market competition. Selecting high-quality components, adopting advanced soldering technology, introducing automated production lines and establishing a complete quality control system are all key measures to enhance product competitiveness. Through continuous improvement and innovation, enterprises can stand out in the fierce market competition and win more customers and market share.

-

Delivery Service

-

Payment Options