- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

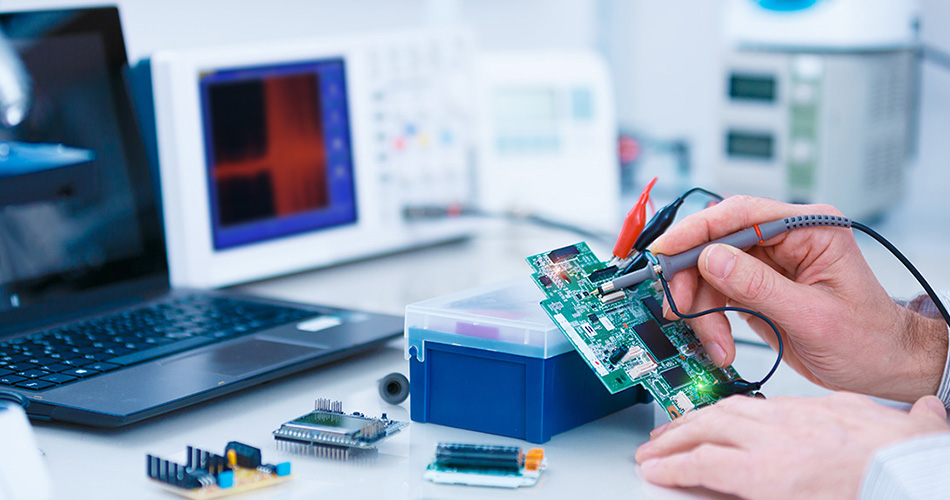

Design for Manufacturability Principles in PCBA Processing

2025-01-02

In PCBA (Printed Circuit Board Assembly) processing, the design stage of manufacturability (DFM) principles is the key to ensure that products can be produced efficiently and economically. Implementing the design for manufacturability principles can not only reduce production costs and shorten production cycles, but also improve product quality. This article will explore the key strategies for applying the design for manufacturability principles in PCBA processing, including design simplification, standardized component use, reasonable layout, and production process adaptation.

Design simplification

1. Reduce complexity

In PCBA processing, simplifying the design is the basic principle to improve manufacturability. Reducing design complexity can bring the following benefits:

Reduce production difficulty: Simple designs are easier to manufacture and assemble, reducing the possibility of problems in the production process.

Reduce errors and rework: Simple circuit design and layout reduce the risk of design errors and reduce rework rates.

Implementation strategy: Try to avoid overly complex circuits and multilayer board designs, and use standardized designs to simplify PCB structures.

2. Modular design

Modular design splits complex circuits into multiple functional modules, each of which is independently designed and tested, which helps:

Simplify assembly: Modular design makes the assembly process simpler and reduces the difficulty of assembly.

Improve maintainability: When problems occur, the problematic modules can be quickly located and replaced to improve maintenance efficiency.

Implementation strategy: Decompose the circuit design into functional units and design standardized module interfaces to facilitate subsequent production and maintenance.

Use of standardized components

1. Select standardized components

The use of standardized electronic components can significantly improve the manufacturability of PCBA processing. Key strategies include:

Component selection: Give priority to standardized components that are common and easy to purchase on the market, and avoid using customized or uncommon parts.

Consistency: Maintain the consistency of component specifications and packaging to reduce the mixing of different types of components.

Implementation strategy: Manage the component library during the design stage and select standardized and highly compatible components to ensure that they are compatible with production line equipment.

2. Optimize pad design

The optimization of pad design is crucial to improve soldering quality and production efficiency, including:

Pad size: Design pads of appropriate size to ensure matching with component feet and prevent soldering problems.

Spacing design: Maintain sufficient spacing to avoid short circuits and interference between pads.

Implementation strategy: Follow the industry standard pad design specifications and optimize pads according to the actual specifications of the components.

Reasonable layout

1. Optimize circuit layout

Reasonable circuit layout can not only improve production efficiency, but also reduce production defects. Key measures include:

Signal routing: Reasonably plan signal routing, reduce signal interference and crosstalk problems, and optimize circuit performance.

Thermal management: Consider heat distribution, reasonably layout heating components, and avoid failures caused by overheating.

Implementation strategy: Consider electrical performance, thermal management, and physical space in layout design, and avoid complex wiring and overly dense layout.

2. Component layout

Reasonable component layout helps simplify the assembly process and improve production efficiency. Includes:

Component arrangement: Arrange components on the PCB according to assembly order and function to facilitate automated assembly.

Access space: Reserve sufficient space for maintenance and inspection to ensure that components are easy to access and operate.

Implementation strategy: Optimize component layout to ensure the convenience of assembly and maintenance processes and reduce interference and operational difficulty in production.

Production process adaptation

1. Adapt production equipment

The design should take into account the capabilities and limitations of production equipment to ensure that the design can be produced smoothly. Includes:

Equipment compatibility: Ensure that the design meets the requirements of existing production equipment, such as the specifications of placement machines and soldering equipment.

Process requirements: Adjust the design according to the requirements of the production process to ensure that the design can adapt to the automated production process.

Implementation strategy: Work closely with the production team during the design stage to understand the specifications and process requirements of the production equipment and optimize the design to improve production adaptability.

2. Testing and verification

After the design is completed, conduct sufficient testing and verification to ensure that the design can be produced and operated smoothly. Includes:

Prototype testing: Make a prototype for testing to verify the functionality and manufacturability of the design.

Process verification: Work with the production team to verify the adaptability and feasibility of the design in actual production.

Implementation strategy: Conduct comprehensive testing and verification, adjust the design in time to solve the problems found, and improve the production adaptability of the design.

Conclusion

Applying the principles of design for manufacturability in PCBA processing can significantly improve production efficiency, reduce production costs and defects. Through strategies such as design simplification, standardized component use, reasonable layout and production process adaptation, companies can optimize the design and improve the stability and economy of the production process. Implementing these principles will not only help improve product quality, but also promote the smoothness of the production process, bringing greater competitive advantages to companies.

-

Delivery Service

-

Payment Options