- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

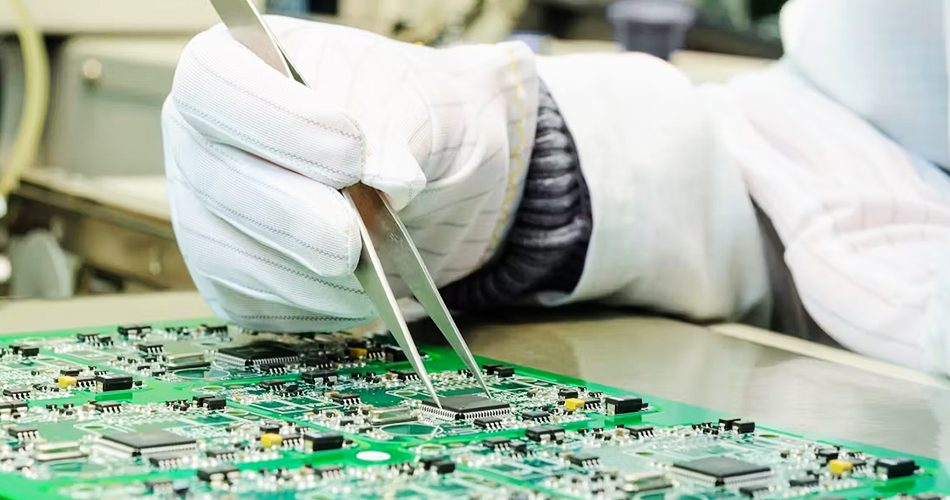

Common circuit board problems in PCBA processing

2025-01-05

During the PCBA (Printed Circuit Board Assembly) processing, various problems may occur in the circuit board, which not only affect the performance of the product, but may also lead to increased production costs. Identifying and solving these common problems is essential to ensure high-quality PCBA processing. This article will explore common circuit board problems in PCBA processing, including cold solder joints, short circuits, open circuits, solder joint defects, and PCB substrate problems, and provide corresponding solutions.

Cold solder joints

1. Problem description

Cold solder joints refer to the failure of solder joints to fully form a reliable connection with the circuit board pads, usually manifested as poor contact of solder joints, resulting in unstable electrical signal transmission. Common causes of cold solder joints include insufficient solder, uneven heating, and too short soldering time.

2. Solutions

Optimize the soldering process: adjust soldering parameters such as temperature, time, and soldering speed to ensure that the solder is completely melted and forms a good connection.

Inspect equipment: Regularly maintain and calibrate soldering equipment to ensure its normal operation.

Perform visual inspection: Use a microscope or automated inspection equipment to inspect solder joints to ensure soldering quality.

Short circuit

1. Problem description

A short circuit refers to the accidental contact of two or more circuit parts on a circuit board that should not be connected, resulting in abnormal current flow. Short circuit problems are usually caused by solder overflow, copper wire shorting, or contamination during the production process.

2. Solution

Control the amount of solder: avoid solder overflow and ensure that the solder joints are clean and neat.

Clean PCB: Keep the PCB clean during the production process to prevent contaminants from causing short circuits.

Use automatic detection: Apply automated detection systems (such as AOI) to quickly identify short circuit problems.

Open circuit

1. Problem description

An open circuit refers to the failure of certain lines or solder joints on the circuit board to form an electrical connection, causing the circuit to not work properly. Open circuit problems are common in soldering defects, PCB substrate damage, or design errors.

2. Solution

Check solder joints: Make sure all solder joints are properly connected and the amount of solder is sufficient.

Repair PCB: Repair or replace physically damaged PCB substrates.

Verify design: Strictly verify the circuit board design before production to ensure that the design is correct.

Solder joint defects

1. Problem description

Solder joint defects include cold solder joints, cold solder joints, solder balls and solder bridges, which can affect the mechanical strength and electrical performance of solder joints.

2. Solutions

Control soldering temperature and time: Ensure that the temperature and time during the soldering process are optimal to avoid solder joint defects.

Use high-quality materials: Select high-quality solder and flux to reduce the occurrence of solder joint defects.

Perform solder joint inspection: Use a microscope or other inspection tools to inspect solder joints to ensure their quality.

PCB substrate problems

1. Problem description

PCB substrate problems include substrate warping, interlayer peeling and cracking. These problems are usually caused by improper operation or material defects during the manufacturing process.

2. Solutions

Select high-quality materials: Use high-quality PCB substrate materials to reduce the occurrence of substrate problems.

Control the production environment: Maintain the stability of the production environment and avoid drastic changes in temperature and humidity.

Strict production control: Strictly control the handling and processing of the substrate during the production process to avoid damage to the substrate.

Summary

During the PCBA process, common circuit board problems include cold solder joints, short circuits, open circuits, solder joint defects, and PCB substrate problems. By optimizing the soldering process, controlling the amount of solder, cleaning the PCB, checking the solder joints, selecting high-quality materials, and strictly controlling production, the occurrence of these problems can be effectively reduced, and the quality and reliability of PCBA processing can be improved. Regular quality inspections and maintenance are carried out to ensure the smooth progress of the production process, thereby improving the overall performance and market competitiveness of the product.

-

Delivery Service

-

Payment Options