- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

News

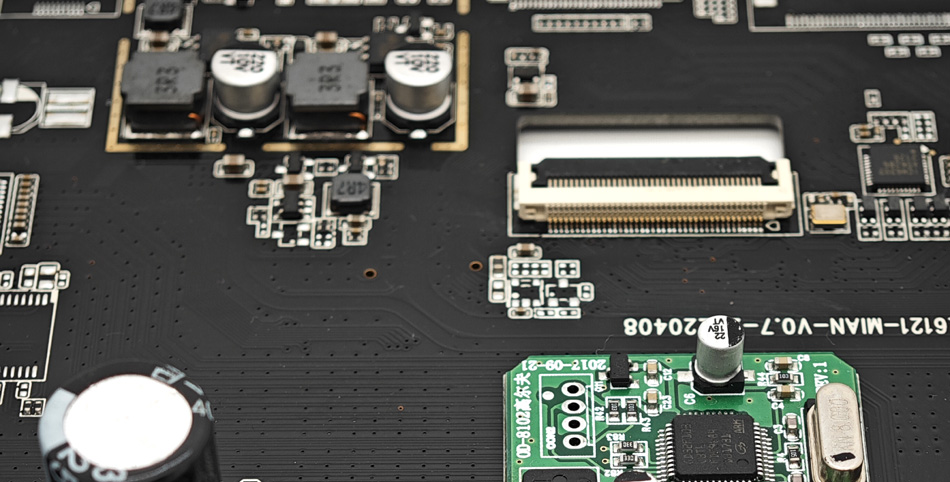

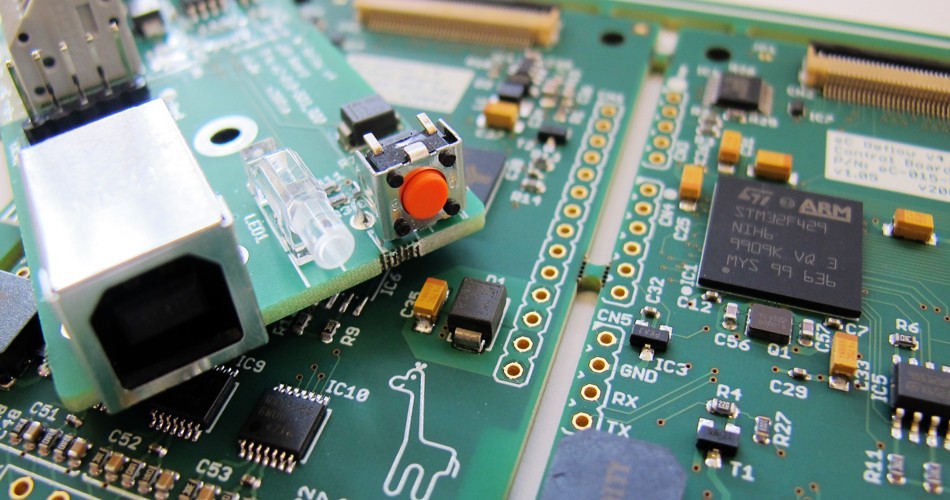

Supplier evaluation and partner selection in PCBA processing

In PCBA (Printed Circuit Board Assembly) processing, supplier evaluation and partner selection are key decisions, which are crucial to product quality, cost, delivery time and the success of the partnership. Here are some key steps and considerations on how to conduct vendor evaluation and select a ......

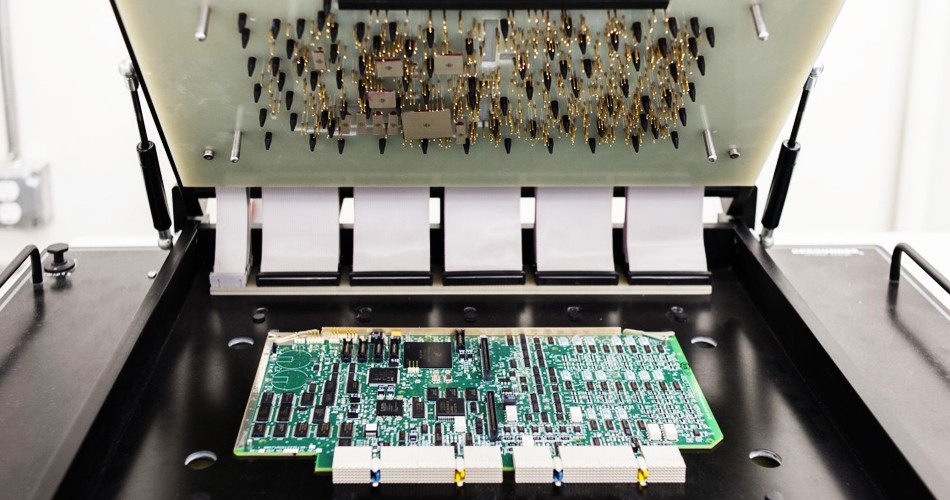

Read MoreTestability and design specifications in PCBA design

In PCBA design, testability (Testability) and compliance with design specifications (Design for Manufacturability and Assembly, DFMA) are two key concepts that help ensure the production quality and test feasibility of the circuit board. Here are the details on both:

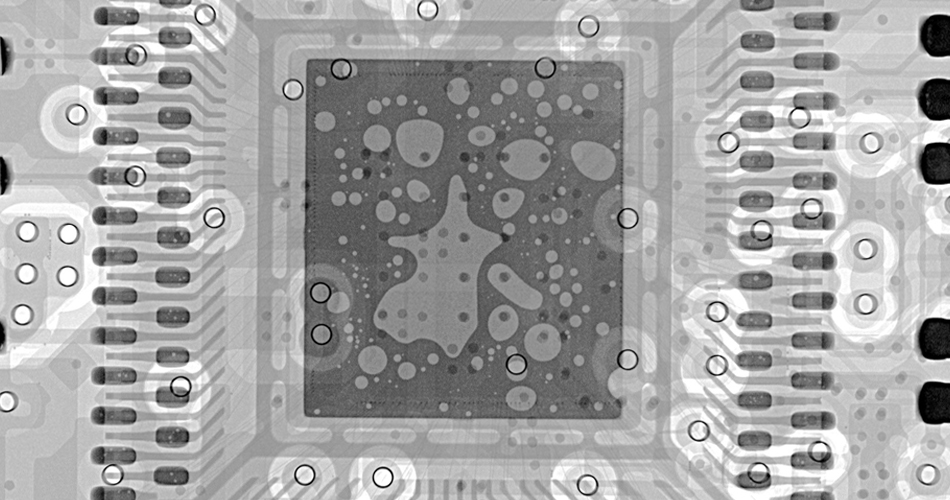

Read MoreNon-destructive testing and quality assurance in PCBA manufacturing

In PCBA (Printed Circuit Board Assembly) manufacturing, non-destructive testing and quality assurance are key engineering practices to ensure the quality, reliability and performance of circuit boards. Here are the details on both:

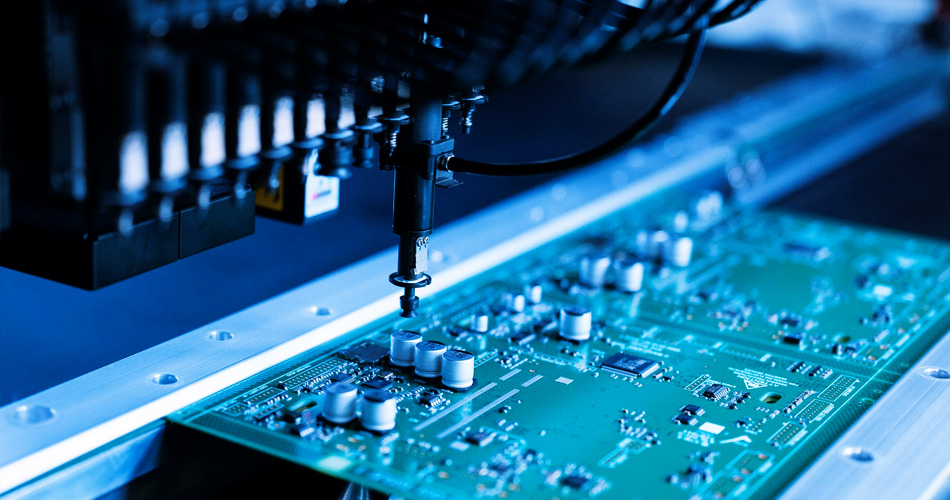

Read MoreFlexible cable routing and board-to-board connections in PCBA assembly

In PCBA assembly, flexible cables and board-to-board connections are two common connection methods that allow signals and power to be transferred between different circuit boards. Here are the details about these two connection methods:

Read MoreElectronic equipment recycling and reuse in PCBA processing

Electronic equipment recycling and reuse are of environmental protection and resource conservation importance in PCBA processing. These practices help reduce the negative environmental impact of discarded electronic equipment and provide opportunities to reduce costs and promote sustainability. Here......

Read More-

Delivery Service

-

Payment Options