- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

News

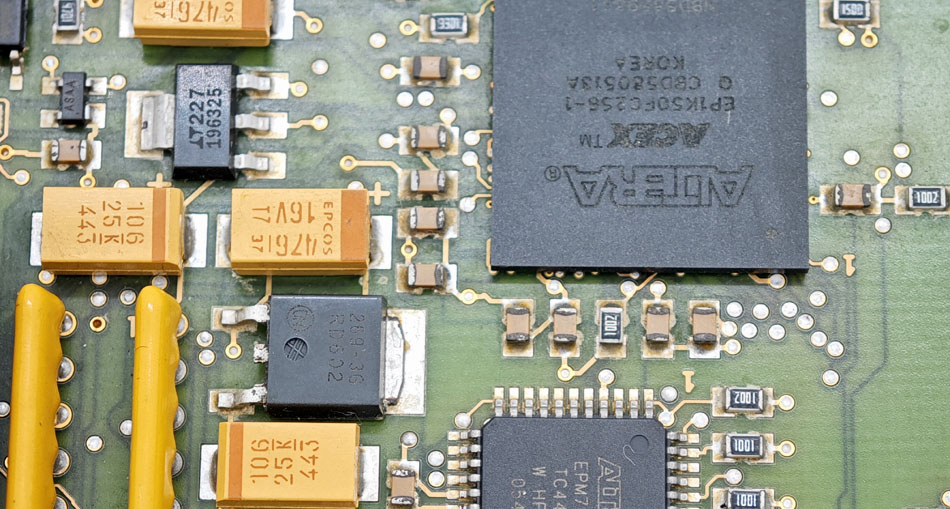

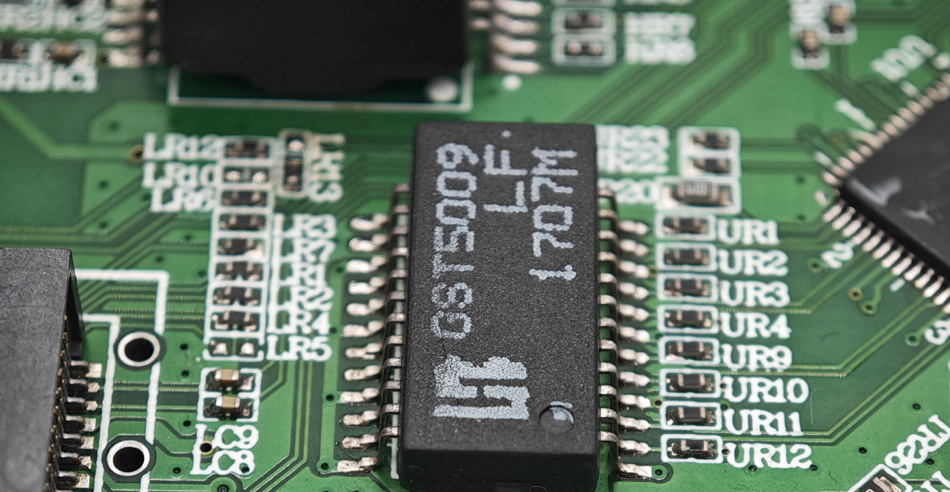

Hardware encryption and data security in PCBA assembly

In PCBA assembly, hardware encryption and data security are very important, especially for devices that handle sensitive information or are connected to the network. Here are some key aspects and strategies regarding hardware encryption and data security:

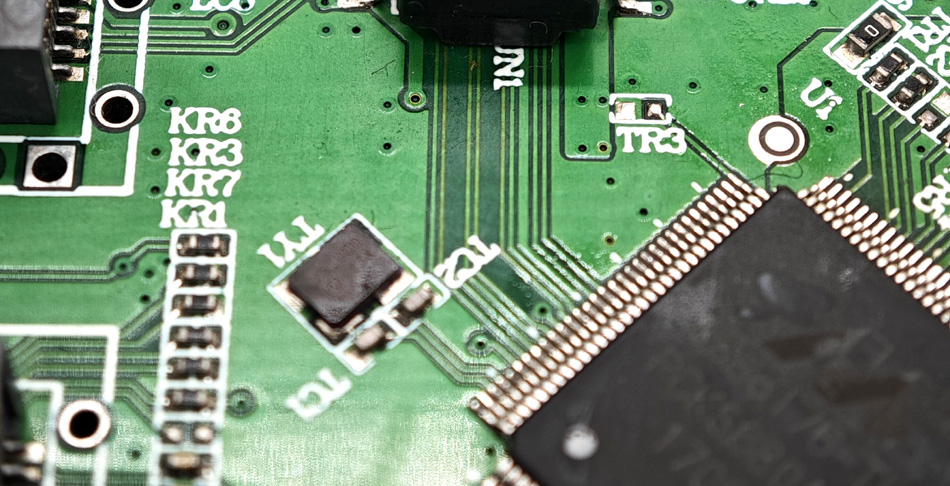

Read MoreTraceability and production record management in PCBA manufacturing

In PCBA manufacturing, traceability and production record management are critical, helping ensure product quality, safety and compliance. Here are some key aspects and strategies regarding traceability and production records management:

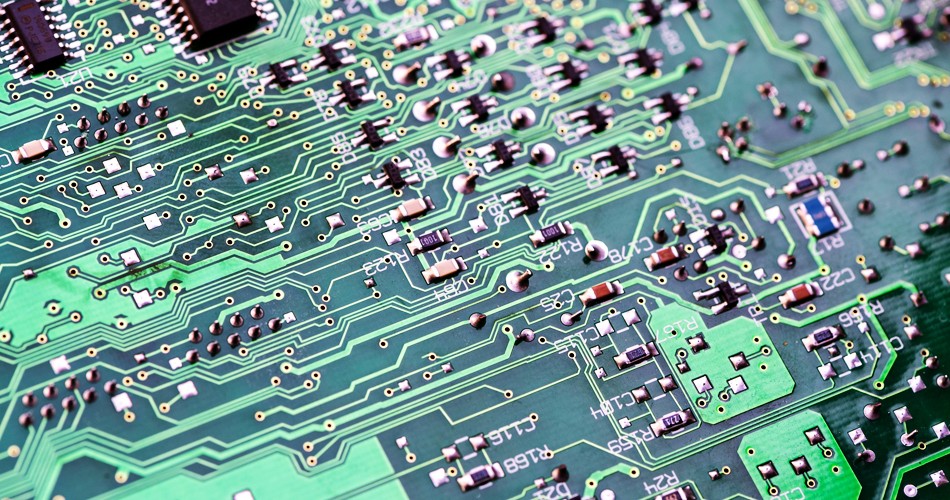

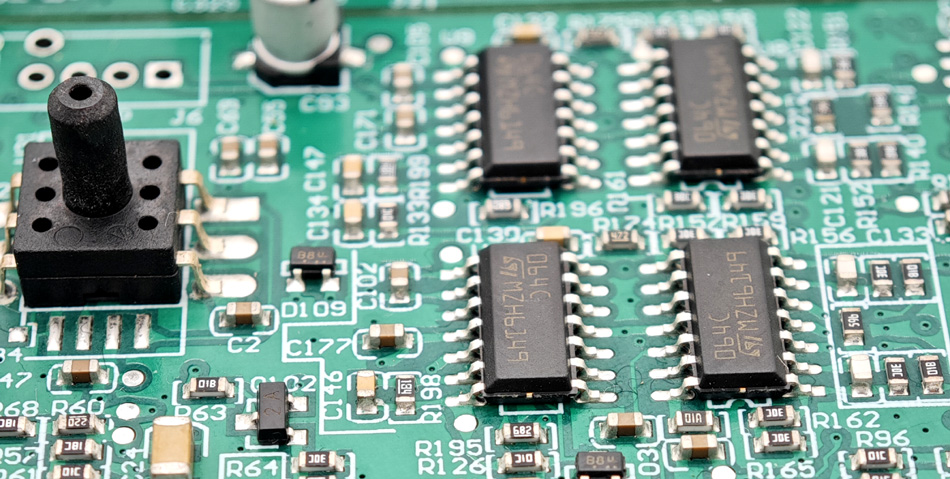

Read MoreSMT technology and process parameters in PCBA processing

Surface Mount Technology (SMT) is very important in PCBA processing because it allows electronic components to be mounted directly on the printed circuit board (PCB), providing an efficient assembly method. Here is some key information about SMT technology and process parameters:

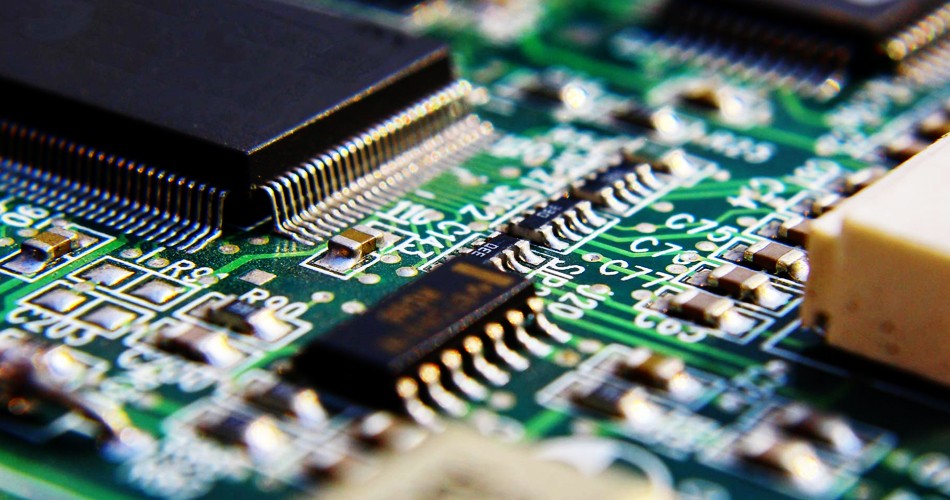

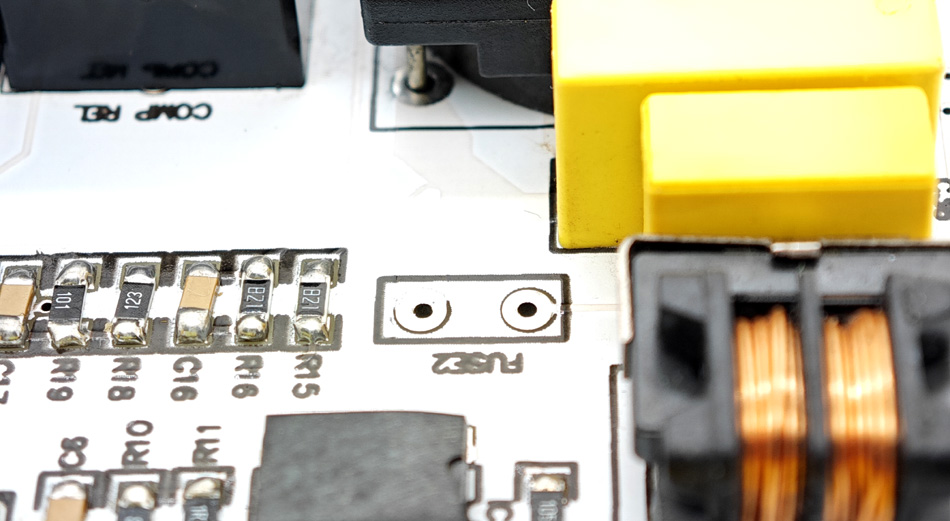

Read MorePower supply noise filtering and voltage stabilization in PCBA assembly

In PCBA assembly, power supply noise filtering and voltage stabilization are crucial as they help ensure the stability of the power supply and reduce noise and interference in electronic equipment. Here are some key aspects and strategies for power supply noise filtering and regulation: Power suppl......

Read MoreRedundant circuits and backup systems in PCBA design

In PCBA design, redundant circuits and backup systems are an important design strategy to improve system reliability and fault tolerance. These strategies can help ensure that in the event of a failure or unexpected situation, the system can still operate normally or quickly switch to a backup mode.......

Read MoreMaterial cost analysis and control in PCBA assembly

In PCBA assembly, material cost is an important component of manufacturing cost. Therefore, it is very critical to carry out material cost analysis and control, which can help manufacturers reduce production costs and increase profits. Here are some key aspects and strategies regarding material cost......

Read MoreElectrostatic discharge (ESD) testing and protection in PCBA manufacturing

In PCBA manufacturing, electrostatic discharge (ESD) testing and protection is critical because ESD can cause damage to electronic components and circuit boards, causing irreversible failure. The following are key aspects and strategies regarding ESD testing and protection: ESD test:

Read MoreRadio frequency interference and suppression strategies in PCBA processing

Radio frequency interference (RFI) is a common problem in PCBA processing, especially for electronic devices containing radio frequency circuits. To ensure the performance and reliability of electronic devices, a series of strategies are needed to suppress radio frequency interference.

Read More-

Delivery Service

-

Payment Options