- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

News

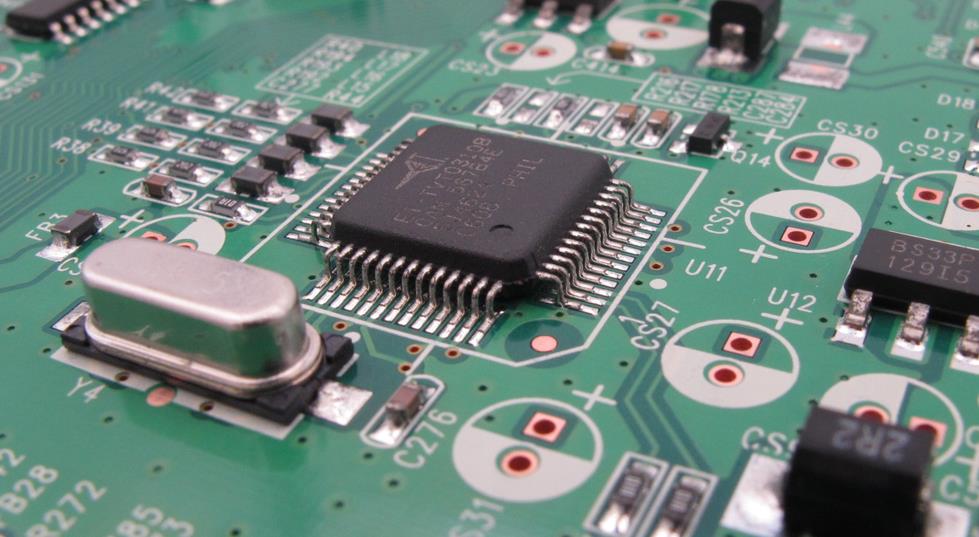

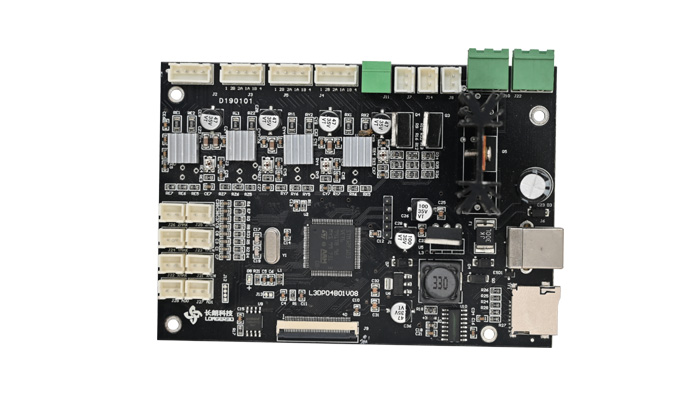

Repeatability testing and calibration in PCBA manufacturing

In PCBA manufacturing, repeatability testing and calibration are critical steps to ensure product quality and performance consistency. These processes help verify the correct functionality of the PCBA while providing a means to monitor and adjust the manufacturing process to maintain consistent prod......

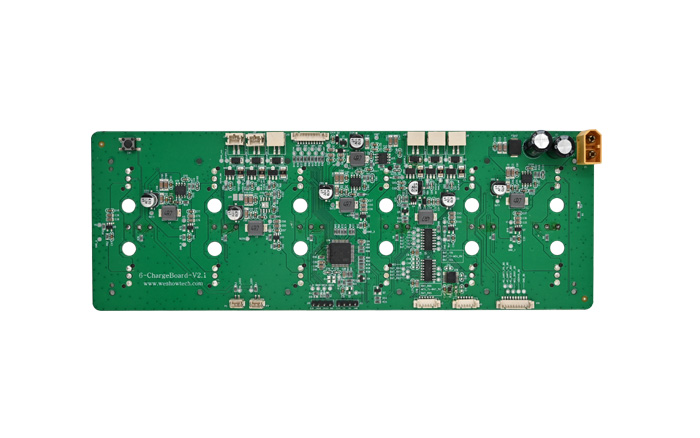

Read MoreCooling technology and thermal fluid analysis in PCBA processing

In PCBA processing, cooling technology and thermal fluid analysis are very important, especially for high-power electronic equipment and dense circuit boards. Here is some key information about cooling technology and thermal fluid analysis:

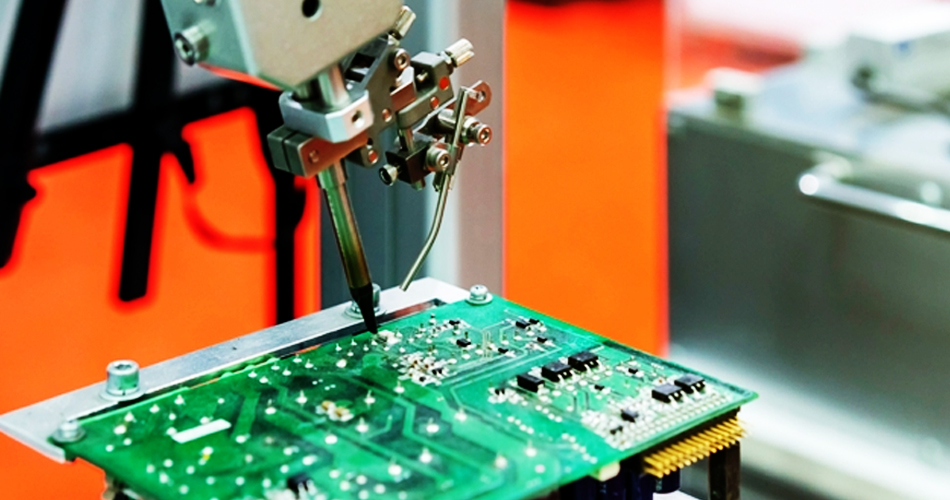

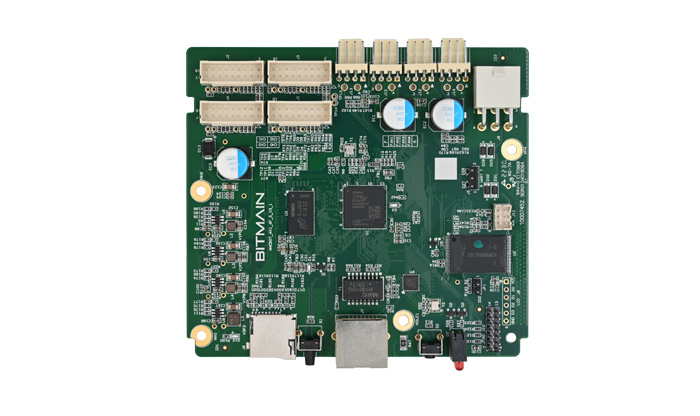

Read MoreIndustrial Robots and Automation Integration in PCBA Assembly

In PCBA assembly, industrial robots and automation integration can significantly improve production efficiency, reduce costs, improve quality, and reduce the occurrence of human errors. Here is key information about the use of industrial robots and automation integration in PCBA assembly: Applicati......

Read MorePCBA Processing Factory Selection Guide: Key Factors Overview

Choosing PCBA and processing plants is one of the important decisions in electronic product manufacturing, affecting product quality, cost and delivery time. Here are some key factors that can serve as a guide when choosing a PCBA processing factory:

Read MoreThe intersection of PCBA processing and medical fields: the digital guardian of life

The application of PCBA processing in the medical field has become the digital guardian of life. It plays a vital role in medical devices, medical instruments and health monitoring systems, helping to improve the quality, efficiency and accessibility of healthcare. The following are key aspects wher......

Read MoreGeographical location of PCBA supplier: Considerations, Advantages and Disadvantages

Choosing the location of your PCBA supplier is an important decision that can impact production efficiency, delivery time, cost, and quality. Here are the factors to consider and the advantages and disadvantages of location: Factors to consider:

Read MoreUnderstanding the PCBA Manufacturing Process: Helping You Make Smart Choices

Understanding the PCBA manufacturing process can help you better understand the process and make informed choices when selecting a supplier or overseeing a project. The following are the key steps that typically cover the PCBA manufacturing process:

Read More-

Delivery Service

-

Payment Options