- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Detailed explanation of high-precision PCBA processing technology

2024-12-15

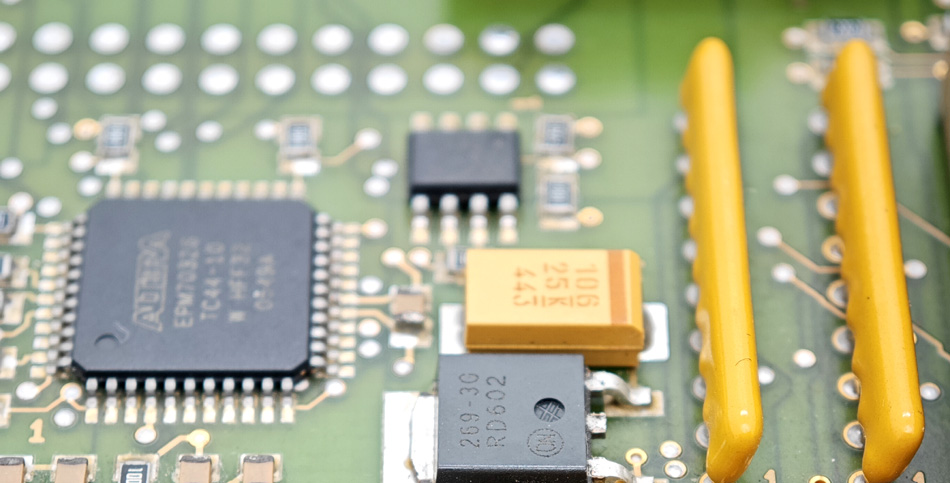

PCBA processing (Printed Circuit Board Assembly) is one of the key links in the manufacturing of electronic products. Its production quality and precision are directly related to the performance and stability of the product. This article will introduce high-precision PCBA processing technology in detail, including its definition, application fields, key technologies and advantages.

1. Overview of high-precision PCBA processing technology

High-precision PCBA processing technology refers to the maintenance of extremely high accuracy and precision when installing, soldering and connecting components on PCB (Printed Circuit Board) circuit boards. This technology is widely used in medical equipment, aerospace, communication equipment and other fields, requiring the installation position, soldering quality and connection lines of components on the circuit board to meet extremely high precision requirements.

2. Application fields of high-precision PCBA processing technology

2.1 Medical equipment

In medical equipment, high-precision PCBA processing technology can ensure the accurate installation and connection of various sensors, monitoring devices and control circuits, and ensure the stable operation and accurate data collection of medical equipment.

2.2 Aerospace

The aerospace field has extremely high requirements for the precision of PCBA processing, because electronic equipment needs to operate in extreme environments, such as high temperature, low temperature, high pressure, etc. High-precision PCBA processing technology can ensure the reliability and safety of the equipment.

2.3 Communication equipment

Communication equipment has very high requirements for the accuracy and stability of signal transmission. High-precision PCBA processing technology can ensure the connection quality of signal lines on the circuit board and improve the performance and reliability of communication equipment.

3. Key technologies of high-precision PCBA processing technology

3.1 Automation equipment

High-precision PCBA processing technology relies on advanced automation equipment, such as automatic placement machines, automatic soldering machines, etc. These equipment can realize the precise installation and soldering of components and improve production efficiency and accuracy.

3.2 Fine process control

Fine process control is one of the keys to high-precision PCBA processing technology, including precise control of soldering temperature, soldering time, component position calibration, etc., to ensure the accuracy and stability of the processing process.

3.3 Quality inspection and verification

High-precision PCBA processing technology needs to be equipped with high-precision quality inspection equipment and verification methods, and strict quality inspection and verification of the processed circuit boards are carried out to ensure that the products meet the design requirements and customer needs.

4. Advantages and characteristics of high-precision PCBA processing technology

4.1 Improve product quality

High-precision PCBA processing technology can effectively improve product quality and stability, reduce product failure rate and maintenance costs, and improve customer satisfaction.

4.2 Improve production efficiency

Through automated equipment and fine process control, high-precision PCBA processing technology can improve production efficiency, shorten production cycle, and reduce production costs.

4.3 Adapt to diverse needs

High-precision PCBA processing technology is flexible and customizable, and can adapt to the diverse needs of different products and customers, and provide personalized solutions.

Conclusion

High-precision PCBA processing technology plays an important role in the field of modern electronic manufacturing. It can not only improve product quality and production efficiency, but also meet diverse customer needs. With the continuous development and application of technology, high-precision PCBA processing technology will continue to play an important role in promoting the continuous innovation and development of the electronics industry.

-

Delivery Service

-

Payment Options