- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

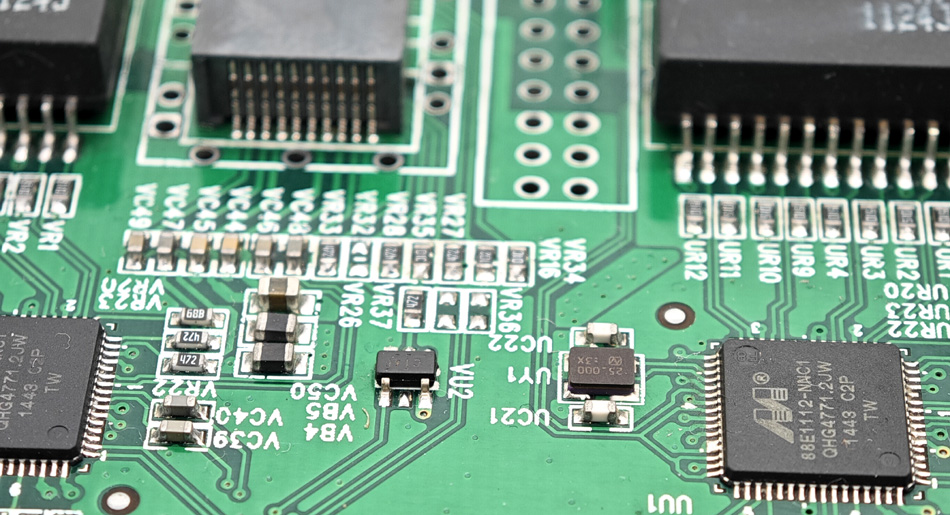

Process optimization in PCBA processing

2024-12-16

PCBA processing (Printed Circuit Board Assembly) is one of the important links in the manufacturing process of electronic products. The optimization of process flow is of vital importance to improving production efficiency, reducing costs and improving product quality. This article will discuss the optimization of process flow in PCBA processing, including optimization methods, key factors and application cases.

1. The significance of process flow optimization

1.1 Improving production efficiency

Optimizing the process flow can simplify the operation steps, reduce unnecessary waiting time and handover links, and improve production efficiency and production capacity.

1.2 Reducing production costs

Optimizing the process flow can reduce the scrap rate, increase the first-time pass rate, reduce the cost of raw materials and labor, and increase production benefits.

1.3 Improving product quality

Optimizing the process flow can reduce human operation errors, improve process stability and consistency, and ensure product quality and stability.

2. Process flow optimization method

2.1 Value stream map analysis

By drawing a value stream map, analyze the value flow and non-value flow in the production process, and find out the process bottlenecks and optimization space.

2.2 Standardized operation process

Develop standardized operation process and operation instructions, clarify operation steps and standard requirements, and improve the operator's work efficiency and accuracy.

2.3 Continuous improvement

Continuously improve the process flow, and continuously optimize the process flow through methods such as PDCA cycle (Plan-Do-Check-Act) to improve production efficiency and product quality.

3. Key elements

3.1 Advanced equipment

Select advanced production equipment and process equipment to improve production automation and production efficiency and reduce manual intervention.

3.2 Material quality control

Strictly control the quality of raw materials and components to ensure the stability of the supply chain and the controllability of product quality.

3.3 Personnel training and management

Strengthen employee training and skills improvement to ensure that operators are proficient in process flow and operating specifications, and reduce operating errors and quality problems.

4. Application Cases

An electronic manufacturing company optimized the PCBA processing process, adopted automated production equipment, standardized operating procedures and continuous improvement methods, and achieved a production efficiency increase of more than 30%, a scrap rate reduction of 20%, and improved product quality stability.

Conclusion

Process optimization is one of the key links in the PCBA processing process, which is of great significance for improving production efficiency, reducing costs and improving product quality. Enterprises should adopt appropriate optimization methods and key elements according to actual conditions, continuously improve process flows, continuously improve production efficiency and competitiveness, and promote the development and progress of the electronic manufacturing industry.

-

Delivery Service

-

Payment Options