- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

How to reduce product failure rate through PCBA processing

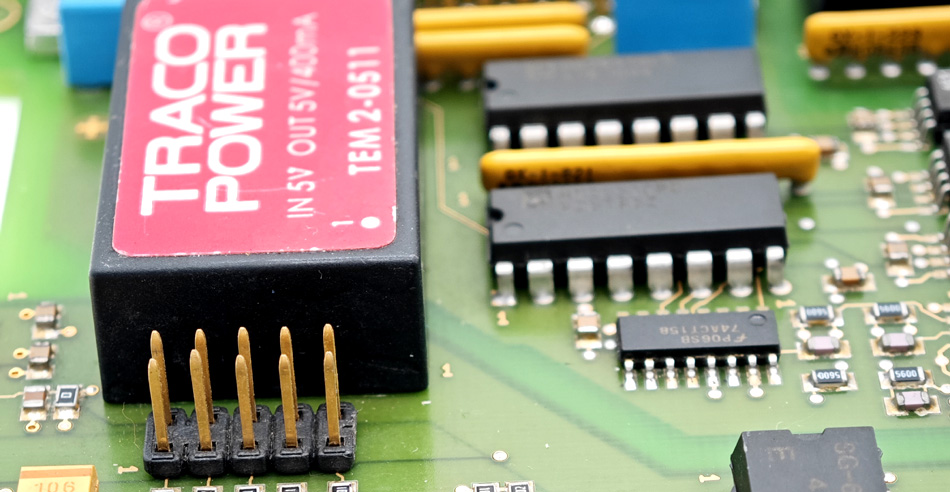

In the modern electronic manufacturing industry, the quality of PCBA (Printed Circuit Board Assembly) processing is directly related to the performance and reliability of the final product. Reducing product failure rate can not only improve customer satisfaction, but also reduce after-sales service costs and improve corporate reputation. This article will explore effective ways to reduce product failure rate by optimizing PCBA processing.

1. Select high-quality raw materials

The first step in PCBA processing is to select high-quality raw materials, including circuit boards, components and soldering materials. High-quality raw materials are the basis for ensuring the quality of PCBA processing.

1.1 Circuit board materials

Choosing circuit board materials with good heat resistance and stable dimensions can effectively avoid warping or delamination during high-temperature soldering.

1.2 Electronic components

Ensure that the source of components is reliable and meets relevant standards. It is recommended to select certified suppliers to ensure the performance and consistency of components.

1.3 soldering materials

Choosing soldering materials that meet international standards, especially lead-free solder, can effectively improve soldering quality and reduce problems such as solder joints and leaks.

2. Optimize design and process flow

In PCBA processing, optimizing design and process flow is an important link to reduce product failure rate.

2.1 Design stage

In the design stage, the manufacturability and testability of PCBA should be fully considered. Adopt reasonable component layout and routing design to avoid overcrowded or irregular wiring, reduce electromagnetic interference and signal integrity problems.

2.2 Process flow

Optimize the process flow, including patch, reflow soldering and wave soldering, to ensure that each step is strictly in accordance with the standard operation. The use of advanced automation equipment and technology, such as automatic optical inspection (AOI) and X-ray inspection (X-Ray), can improve processing accuracy and quality.

3. Strengthen quality control

In PCBA processing, strict quality control is an important guarantee to ensure product reliability.

3.1 Incoming material inspection

All raw materials entering the factory are strictly inspected to ensure that they meet quality standards. Including appearance and performance inspection of circuit boards, components and soldering materials.

3.2 Process Control

During the production process, comprehensive quality control measures are implemented, including environmental control, equipment calibration and operator training. Through regular sampling inspection, problems in the production process are discovered and corrected in a timely manner.

3.3 Final Inspection

Before the product leaves the factory, comprehensive functional testing and reliability testing are carried out to ensure that each product meets the design requirements and quality standards. Including electrical performance testing, thermal cycle testing and aging testing.

4. Introducing advanced testing equipment

Advanced testing equipment can effectively improve the quality of PCBA processing and reduce product failure rate.

4.1 Automatic Optical Inspection (AOI)

AOI equipment can perform comprehensive appearance inspection of circuit boards, identify problems such as solder joint defects and component misalignment, and improve inspection efficiency and accuracy.

4.2 X-ray Inspection (X-Ray)

X-ray inspection equipment can perform internal inspection of solder joints, find internal defects of solder joints that cannot be identified by the naked eye, such as cold solder joints and voids, and improve soldering quality.

4.3 Online Testing (ICT)

Online testing equipment can conduct comprehensive electrical performance tests on circuit boards to ensure that each circuit board meets the design requirements and reduce product failures caused by unqualified electrical performance.

5. Continuous improvement and employee training

Continuous improvement and employee training are long-term guarantees for reducing product failure rates.

5.1 Continuous Improvement

Through data analysis and feedback, continuously optimize PCBA processing processes and processes, solve problems that arise in the production process, and improve product quality.

5.2 Employee Training

Regularly train employees to improve their operating skills and quality awareness. In particular, special training and assessments are conducted for operators of key processes to ensure that they have operational capabilities.

Conclusion

By selecting high-quality raw materials, optimizing design and process flow, strengthening quality control, introducing advanced testing equipment, and continuous improvement and employee training, the product failure rate in PCBA processing can be effectively reduced.

Send Inquiry

-

Delivery Service

-

Payment Options