- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

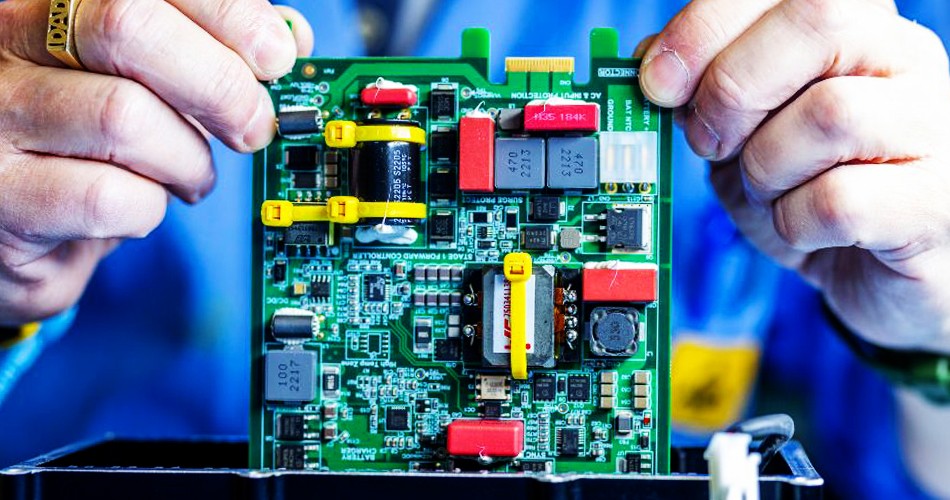

Supply Chain Management Strategy in PCBA Processing

2024-12-29

Supply Chain Management plays a vital role in the PCBA (Printed Circuit Board Assembly) processing process. Efficient supply chain management can not only ensure the smooth progress of production, but also improve product quality and reduce costs. This article will explore the methods of implementing effective supply chain management strategies in PCBA processing, including supplier selection, inventory management, logistics optimization and risk management.

Importance of Supply Chain Management

In PCBA processing, supply chain management involves the entire process from raw material procurement to finished product delivery. Efficient supply chain management can bring the following benefits:

Ensure the supply of raw materials: Ensure that the raw materials required for production are in place in time to avoid production interruptions.

Improve production efficiency: Optimize production processes and reduce production cycles and costs.

Improve product quality: Ensure that products meet standards through strict supplier management and quality control.

Supply Chain Management Strategy

1. Supplier Selection and Management

a. Select reliable suppliers

Selecting the right supplier is a crucial step in PCBA processing. The following factors should be considered:

Supplier Qualification: Evaluate the supplier's qualification certification and production capacity to ensure that it can provide high-quality raw materials.

Delivery capability: Review the supplier's delivery record and capability to ensure that it can deliver the required materials on time.

Price and service: Consider factors such as price, service quality and technical support, and select suppliers with high cost performance.

Advantages: Ensure the quality of raw materials and the stability of supply, and provide a solid foundation for PCBA processing.

b. Establish a long-term cooperative relationship

Establishing a long-term and stable cooperative relationship with suppliers helps:

Stabilize the supply chain: Through long-term cooperation, both parties can establish a trusting relationship and ensure the stability of supply.

Get preferential conditions: Long-term cooperation may obtain better price and service conditions and reduce procurement costs.

Advantages: Improve the stability and reliability of the supply chain and optimize procurement costs.

2. Inventory management

a. Implement precise inventory control

Precise inventory management can effectively reduce inventory backlogs and shortages. Key measures include:

Demand forecasting: Predict future demand through data analysis and arrange inventory levels reasonably.

Inventory classification: Classify and manage materials according to their frequency of use and importance, and optimize inventory configuration.

Advantages: Reduce inventory costs, improve inventory turnover, and avoid production interruptions.

b. Introducing an automated system

The use of an automated inventory management system can improve the efficiency and accuracy of inventory management, including:

Automatic replenishment: The system automatically generates purchase orders based on inventory levels and demand.

Real-time monitoring: Real-time tracking of inventory status and changes, and timely adjustment of inventory strategies.

Advantages: Reduce the complexity of manual management and improve the efficiency and accuracy of inventory management.

3. Logistics optimization

a. Optimizing the logistics network

Optimizing the logistics network can improve transportation efficiency and reduce transportation costs. Key measures include:

Transportation route planning: Select the best transportation route to reduce transportation time and costs.

Logistics partner selection: Select a reliable logistics service provider to ensure timely delivery.

Advantages: Improve logistics efficiency, reduce transportation costs, and ensure that production materials arrive in time.

b. Implement supply chain visualization

Supply chain visualization technology can provide real-time transportation and supply chain information, including:

Real-time tracking: Monitor transportation status, and obtain cargo location and estimated arrival time in a timely manner.

Data analysis: Analyze transportation data to identify potential problems and improvement opportunities.

Advantages: Improve the transparency of the supply chain and help make timely adjustments and decisions.

4. Risk Management

a. Identify and assess risks

Identifying and assessing potential risks in the supply chain can help develop response strategies, including:

Supply chain disruptions: Identify factors that may cause supply chain disruptions, such as natural disasters, supplier issues, etc.

Quality risks: Evaluate supplier quality control measures to reduce product quality risks.

Advantages: Reduce the risk of supply chain disruptions and ensure the continuity and stability of production.

b. Develop emergency plans

Developing emergency plans can effectively respond to sudden problems in the supply chain, including:

Alternative suppliers: Establish a list of alternative suppliers to ensure that they can be quickly switched when problems occur with the main supplier.

Emergency logistics: Prepare emergency logistics plans to ensure that supply can be quickly restored in an emergency.

Advantages: Improve the response capabilities of the supply chain and reduce the impact of risks on production.

Conclusion

In PCBA processing, implementing an effective supply chain management strategy is essential to improving production efficiency, reducing costs and ensuring product quality. By selecting reliable suppliers, optimizing inventory management, improving logistics efficiency and conducting risk management, companies can build an efficient and stable supply chain system. Continuously optimizing supply chain management strategies will help us cope with market changes, maintain competitive advantages, and achieve sustainable development.

-

Delivery Service

-

Payment Options