- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

How to achieve product personalization through PCBA processing

2025-01-07

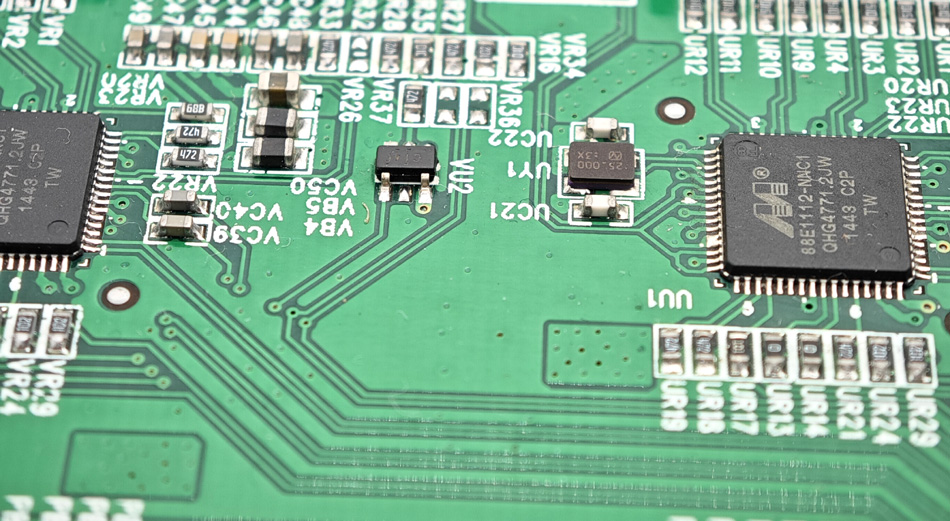

In today's highly competitive market environment, product personalization has become an important strategy for companies to attract customers and increase market share. Product personalization through PCBA (Printed Circuit Board Assembly) processing can not only meet the specific needs of customers, but also enhance the uniqueness and added value of products. This article will explore how to achieve product personalization in PCBA processing, including strategies in customized design, flexible production, personalized testing and small batch production.

Customized design

1. Design flexibility

In PCBA processing, the first step to personalization is customized design. This includes:

Circuit design: Personalize the circuit design according to the specific needs and application scenarios of customers. Designers can adjust the circuit diagram and component layout according to specific functional requirements.

Package selection: Select the appropriate component package and specifications to meet the unique requirements of the product. Different package types can affect the volume, performance and cost of the product.

Implementation strategy: Communicate closely with customers to understand their needs and personalize the design through flexible design tools and technologies.

2. Functional expansion

By introducing additional functional modules in the design stage, the product can have more personalized features. For example:

Adding functional modules: According to customer needs, add additional functional modules such as sensors, communication modules, etc. to the circuit board.

Customized interface: According to the specific application of the product, design customized interfaces and connection methods.

Implementation strategy: Perform functional requirements analysis in the design stage to convert customer needs into specific circuit functions and interface designs.

Flexible production

1. Diversified production lines

During the PCBA processing process, the personalized production of products can be achieved through flexible production line configuration. This includes:

Adjustable production equipment: Use adjustable production equipment such as placement machines and soldering equipment to support components of different specifications and types.

Modular production: Through modular production lines, the production process can be quickly adjusted to adapt to different product needs.

Implementation strategy: Select equipment that can support multiple production modes and specifications to ensure the flexibility and adaptability of the production line.

2. Intelligent manufacturing

The introduction of intelligent manufacturing technology can achieve efficient production of personalized products. Including:

Automated control: Use automated control systems to monitor and adjust the production process in real time to improve production flexibility.

Data-driven: Use data analysis to optimize production processes and quickly adjust production parameters according to different production needs.

Implementation strategy: Invest in smart manufacturing technology to improve the automation level and production flexibility of production lines.

Personalized testing

1. Customized test plan

In order to ensure the quality and performance of personalized products, it is necessary to develop customized test plans, including:

Functional testing: According to the personalized design requirements of the product, functional testing is carried out to ensure that all customized functions work properly.

Performance evaluation: Perform performance evaluation tests to ensure that the performance of the product in the actual use environment meets the requirements.

Implementation strategy: During the testing phase, design and implement test plans for personalized functions to ensure product quality and performance.

2. Feedback and improvement

Collect test data and customer feedback to improve products. This includes:

Test data analysis: Analyze the data collected during the test, identify potential problems, and optimize them.

Customer feedback: Adjust and improve product design and production processes based on customer feedback.

Implementation strategy: Establish a feedback mechanism to continuously improve product design and production processes and improve the personalized quality of products.

Small batch production

1. Flexible small batch production

Through the small batch production mode, personalized products can be delivered quickly. This includes:

Small batch production: small batch production according to customer needs to reduce inventory and production risks.

Rapid iteration: quickly respond to changes in customer needs and iterate design and production.

Implementation strategy: adopt flexible small batch production methods to ensure that personalized products can be delivered quickly.

2. Cost control

Effective cost control in small batch production is also the key to personalization, including:

Optimize procurement: purchase materials according to small batch production needs to reduce waste and inventory costs.

Production efficiency: control production costs by improving production efficiency and reducing production cycles.

Implementation strategy: control costs in small batch production and improve economic benefits by optimizing procurement and production processes.

Summary

Product personalization through PCBA processing involves many aspects, including customized design, flexible production, personalized testing and small batch production. By implementing these strategies, companies can meet the specific needs of customers and improve the uniqueness and market competitiveness of products. Realizing product personalization not only helps to improve customer satisfaction, but also enhances the competitive advantage of companies in the market.

-

Delivery Service

-

Payment Options