- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

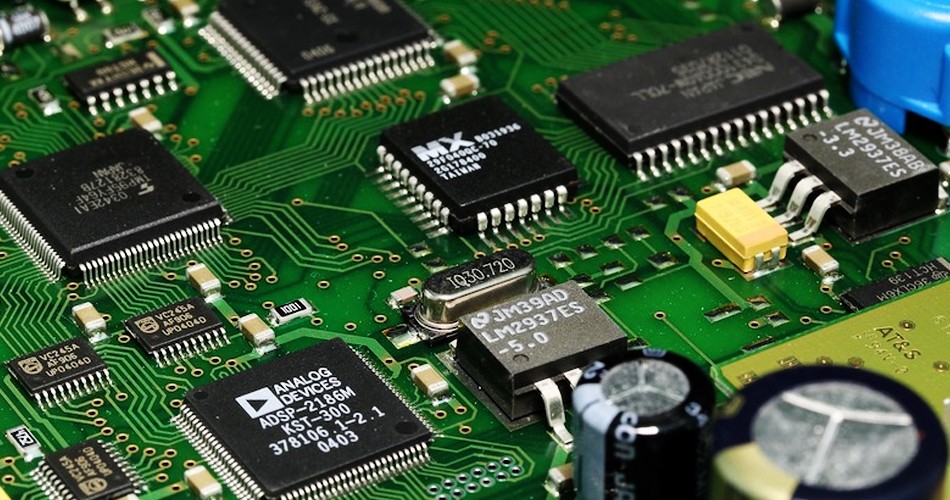

How to optimize the production process in PCBA processing

2025-01-09

In PCBA (Printed Circuit Board Assembly) processing, optimizing the production process can not only improve production efficiency, but also reduce costs and improve product quality. The optimization of the production process involves many aspects, and every step from the design stage to the production process needs to be carefully managed. This article will explore how to optimize the production process in PCBA processing by optimizing design, improving processes, improving equipment utilization, and strengthening quality control.

Design optimization

1. Optimization in the design stage

Optimizing the design is the first step to improve the production process of PCBA processing. Optimization in the design stage can reduce problems in subsequent production and reduce production difficulty.

Design rule check: Use EDA (Electronic Design Automation) tools to perform design rule checks to ensure that the circuit design meets manufacturing requirements.

Simplify the design: Simplify the circuit board design, reduce complexity, and reduce production difficulty. For example, reduce excessive routing and components, optimize the layout, and ensure that the component layout is reasonable.

Design verification: Perform design verification before production, including thermal analysis and electrical analysis, to ensure the manufacturability and reliability of the design.

Implementation strategy: Introduce design rule checking and verification mechanism in the design stage, optimize circuit design, and reduce problems in production.

Process improvement

1. Optimize soldering process

Optimization of soldering process is the key to improving production efficiency and product quality. Including:

Adjust soldering parameters: Adjust soldering temperature, time and solder amount according to different components and soldering requirements to ensure soldering quality.

Automated soldering: Introduce automated soldering equipment to improve soldering consistency and efficiency and reduce errors caused by manual operation.

Conduct process tests: Conduct process tests before formal production to confirm the optimal parameters of the soldering process and avoid problems in production.

Implementation strategy: Optimize soldering process, improve soldering quality and production efficiency, and reduce defect rate.

2. Improve the utilization rate of production equipment

The utilization rate of production equipment directly affects production efficiency and production cost. Including:

Equipment maintenance: Regularly maintain and calibrate production equipment to ensure the normal operation of equipment.

Production scheduling optimization: Reasonably arrange production schedules according to production needs, reduce equipment idle time, and improve equipment utilization.

Equipment upgrade: Introduce advanced production equipment to improve production capacity and production efficiency.

Implementation strategy: Improve the utilization rate of production equipment and reduce production costs through equipment maintenance, production scheduling optimization and equipment upgrade.

1. Implement total quality management

Total quality management (TQM) is an effective way to ensure product quality in PCBA processing. Including:

Quality standard formulation: Detailed quality standards are formulated according to industry standards and customer requirements to ensure that every step in the production process meets quality requirements.

Quality inspection: Perform quality inspections during the production process, including solder joint inspection, functional testing and automatic optical inspection (AOI), to promptly discover and solve problems.

Implementation strategy: Establish a comprehensive quality management system and conduct regular quality inspections to ensure that product quality meets standards.

2. Data-driven quality improvement

Quality improvement through data analysis can effectively improve the optimization effect of the production process. Including:

Collect production data: Record and analyze data in the production process, such as defect rate, production time and equipment operating status, to identify the root cause of the problem.

Implement improvement measures: According to the results of data analysis, implement targeted improvement measures to optimize the production process.

Implementation strategy: Use data-driven analysis and improvement to continuously optimize the production process and improve production efficiency and product quality.

Personnel training

1. Improve operator skills

The skill level of operators directly affects the efficiency and quality of the production process. Including:

Regular training: Provide regular skill training and process knowledge updates for operators to improve their operating ability and problem-solving ability.

Skill assessment: Conduct skill assessment to ensure that operators have the necessary operating and maintenance capabilities.

Implementation strategy: Improve the skill level of operators through training and assessment to ensure the stability and efficiency of the production process.

Summary

Optimizing the production process in PCBA processing involves multiple aspects, including design optimization, process improvement, quality control and personnel training. By optimizing design rules, improving soldering processes, improving equipment utilization, implementing comprehensive quality management and data-driven quality improvement, enterprises can significantly improve production efficiency, reduce production costs, and improve product quality. At the same time, by regularly training operators to ensure their skill level and operating ability, the optimization effect of the production process will be further improved.

-

Delivery Service

-

Payment Options