Why Choose Us

-

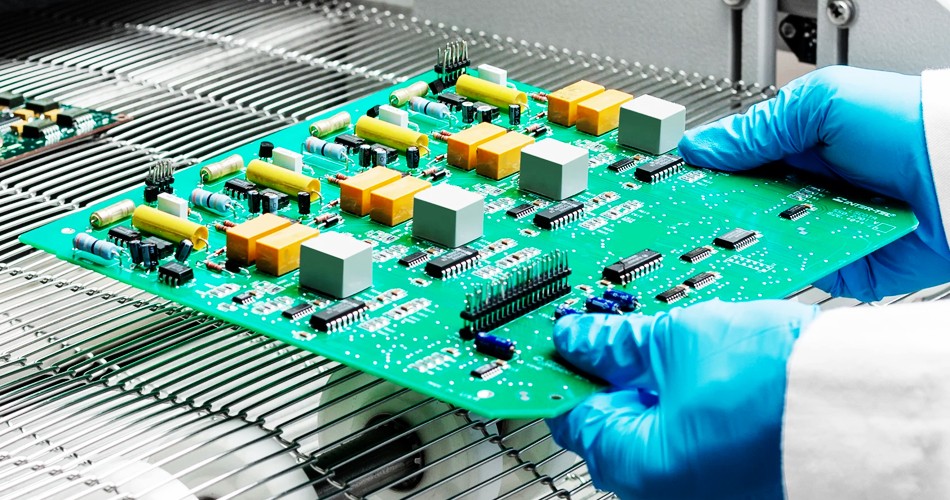

Professionalness

15 years+experience in Electronic Manufacturing project for oversea customers

-

Cost Effectiveness

Skilled procurement team combined with high efficiency manufacturing equipments Make us standing out in cost control.

-

Flexibility

High-mix Low-volume order and no MOQ are acceptable.

-

Quick Turnaround

Unixplore provides two working shifts per day plus 7×24 hours service allowing us to provide quick turnaround for PCBA prototypes in 3 days and 10 days for mass.

-

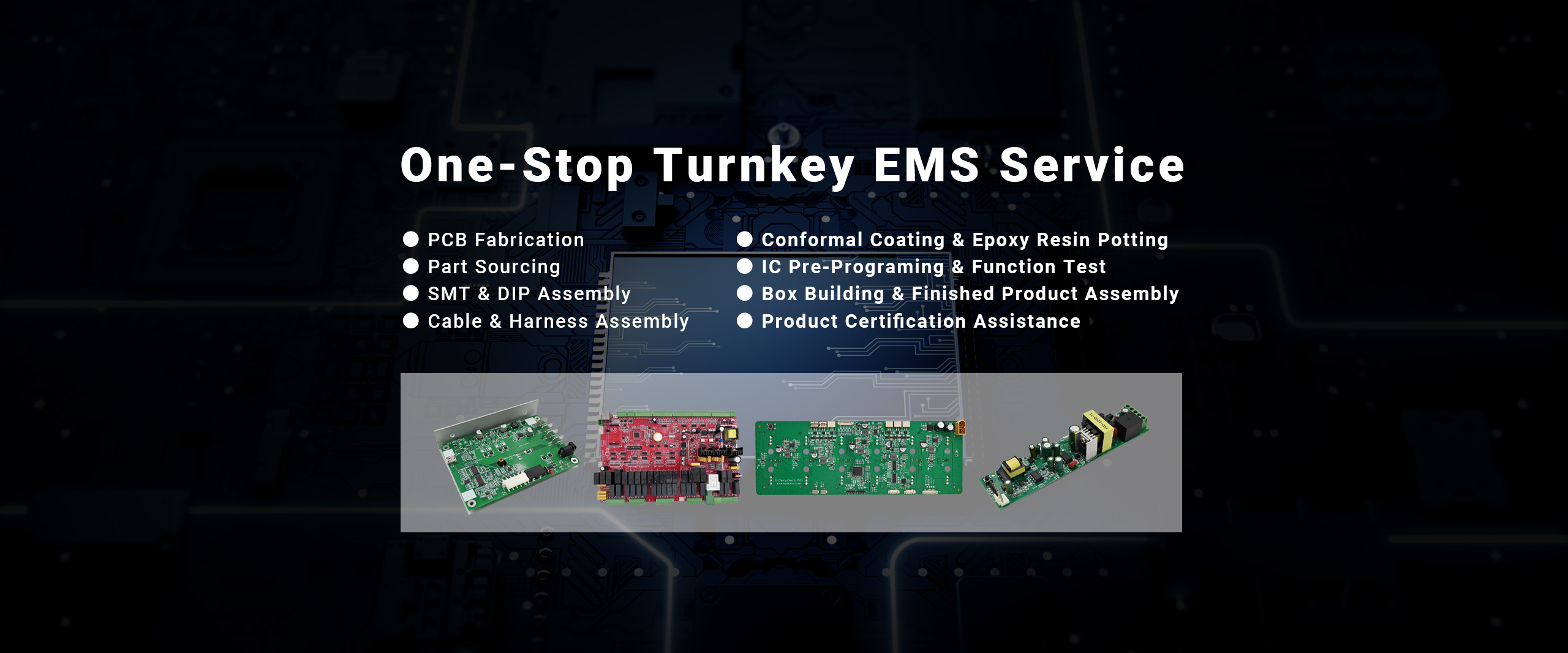

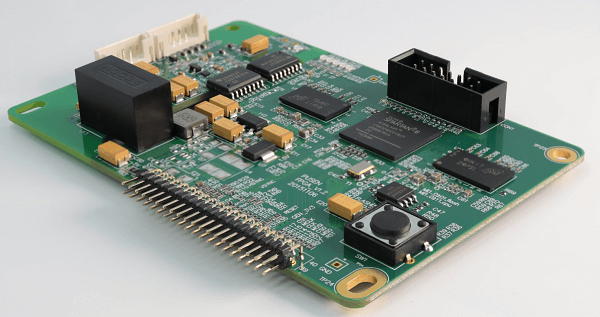

One-Stop Turnkey Service

One-stop service covering PCB,part sourcing,SMT and DIP assembly,programming,function test,box building,conformal coating,finished product assembly, and packaging.

-

Quality Certification

ISO9001:2015, UL, CE, RoHs, IPC-610E,Class II

Our Factory

Customer Testimonials

-

More than happy to give your company good recommendations, we're all really happy with the work you did for us.

Samuel

-

Now we need to compete against the others in quality and price and I think we both are a good team for this.You are doing a great job I know that.

Ingmar

-

congratulation ! we can see that one Linkitall unit has gone online on China Mobile network, the last thing will be solved ... i was just awaked by Jakob , who was happy that he could see a unit online his morning.

Werner

-

Thanks Jerry, that looks very good for me. When you are in the dimensions please do the mass production.

Ulrich

-

Hello Jerry,

Great the 12 working days.

Please take care again with the alignment holes like we had with the ASI2 PCB. I have just paid it so, I assume, you should see it in the coming days.Eddie

-

Hi Jerry,

We received the LED boards last week, thanks. We have now tested a few and they seem to work well as expected. We will probably place an order for trial production before end of the month. nice job!Matthew

-

yes, got them. quality is very satisfying ,

for lense parts it is surely good enough for our application, for other parts it is better than necessary at all.Sergi

-

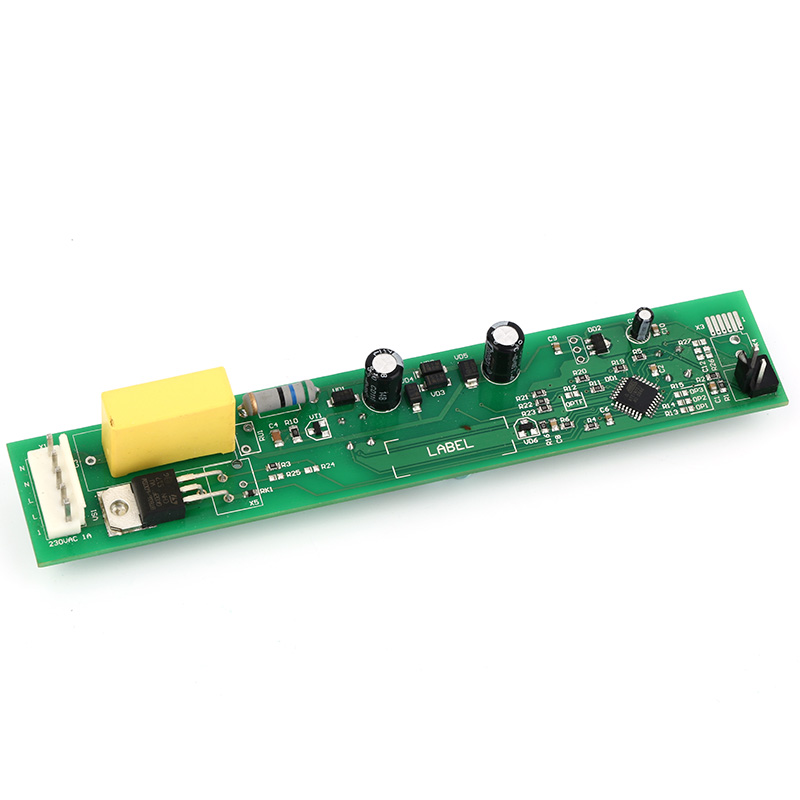

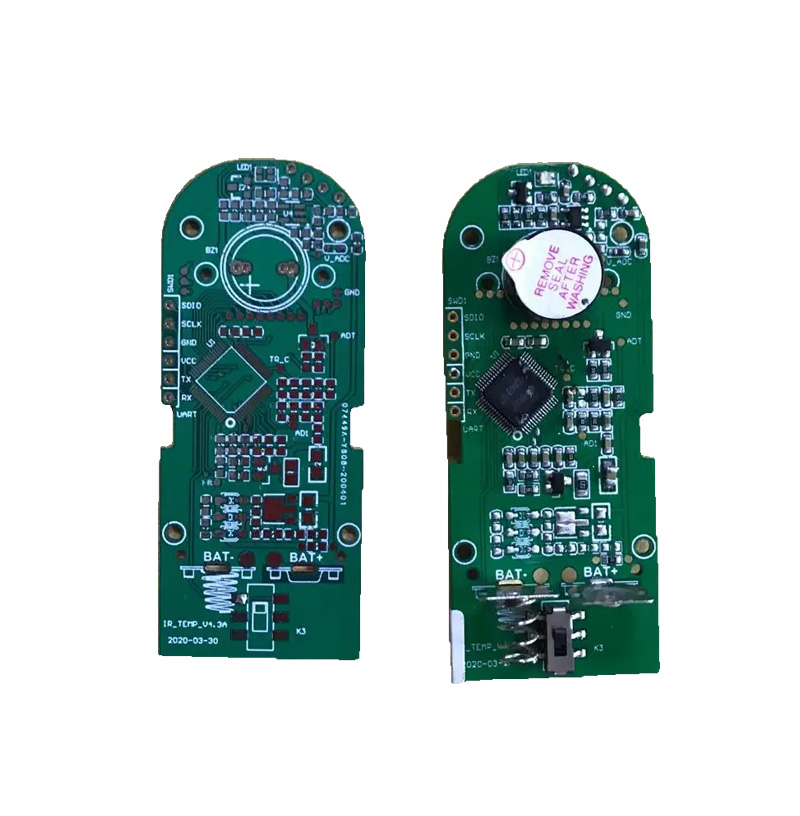

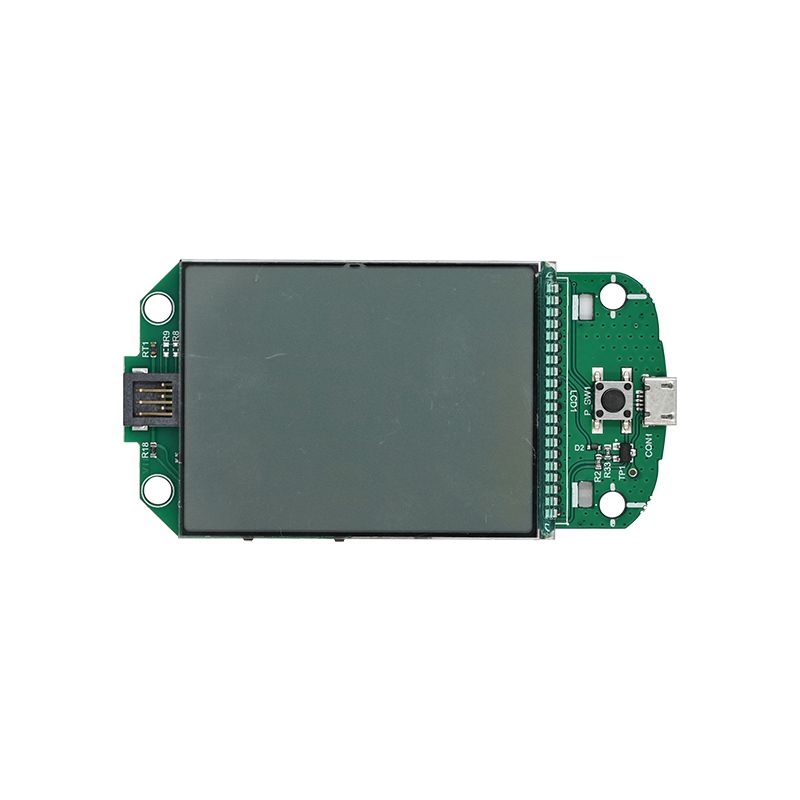

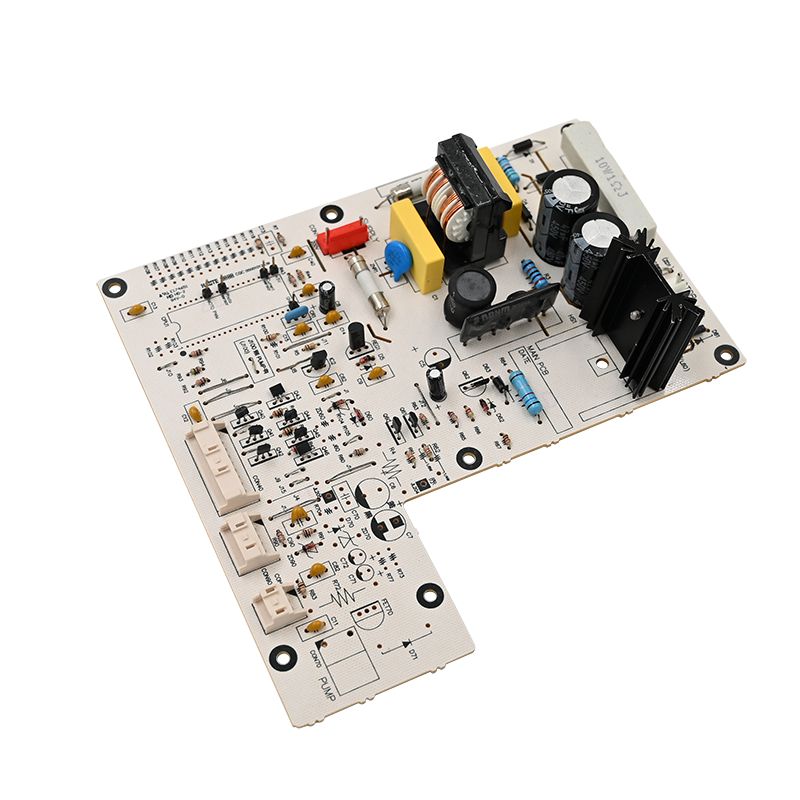

Applications

Home & Kitchen Appliance PCBA

Consumer Electronics PCBA

Automobile Electronic PCBA

Fire Alarm & Security PCBA

Industrial Control & Automation PCBA

Medical Equipment & Healthcare PCBA -

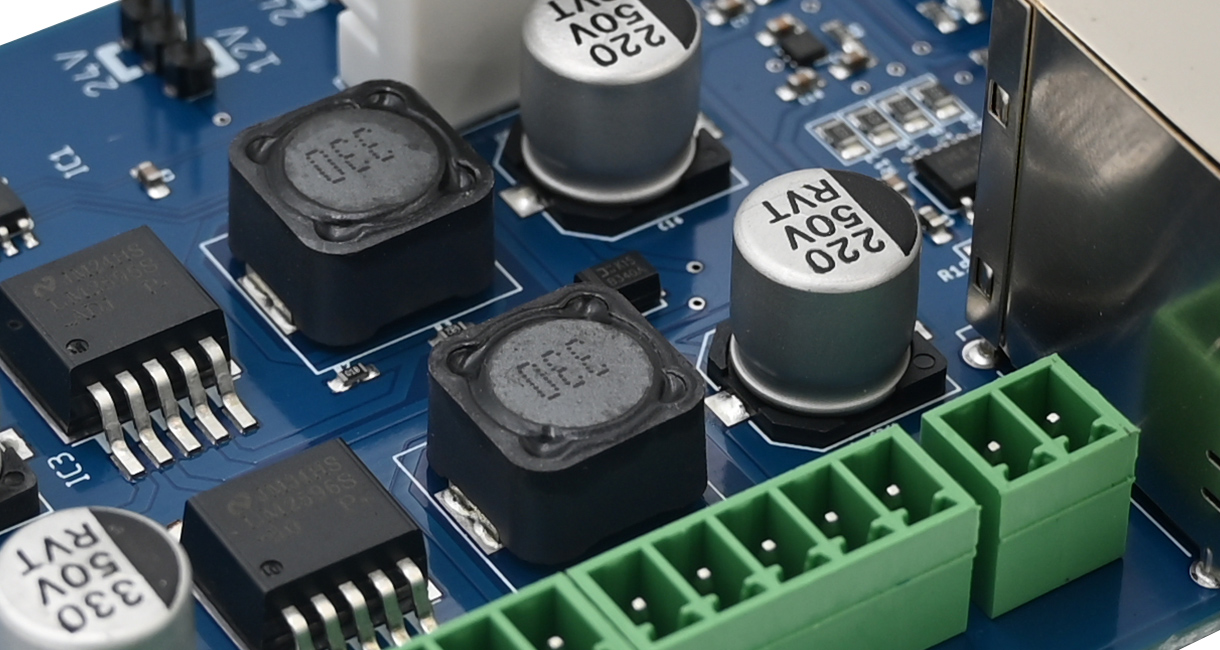

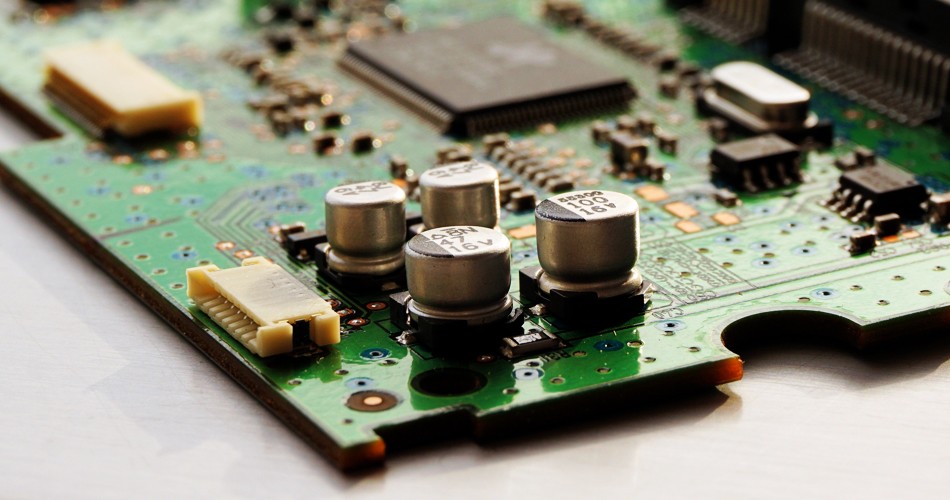

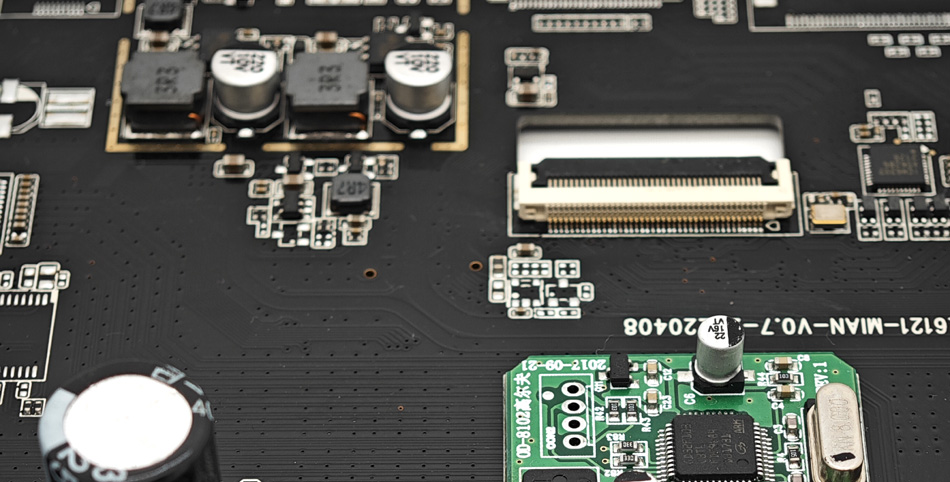

PCB Assembly Service

Turn-Key PCB Assembly Service

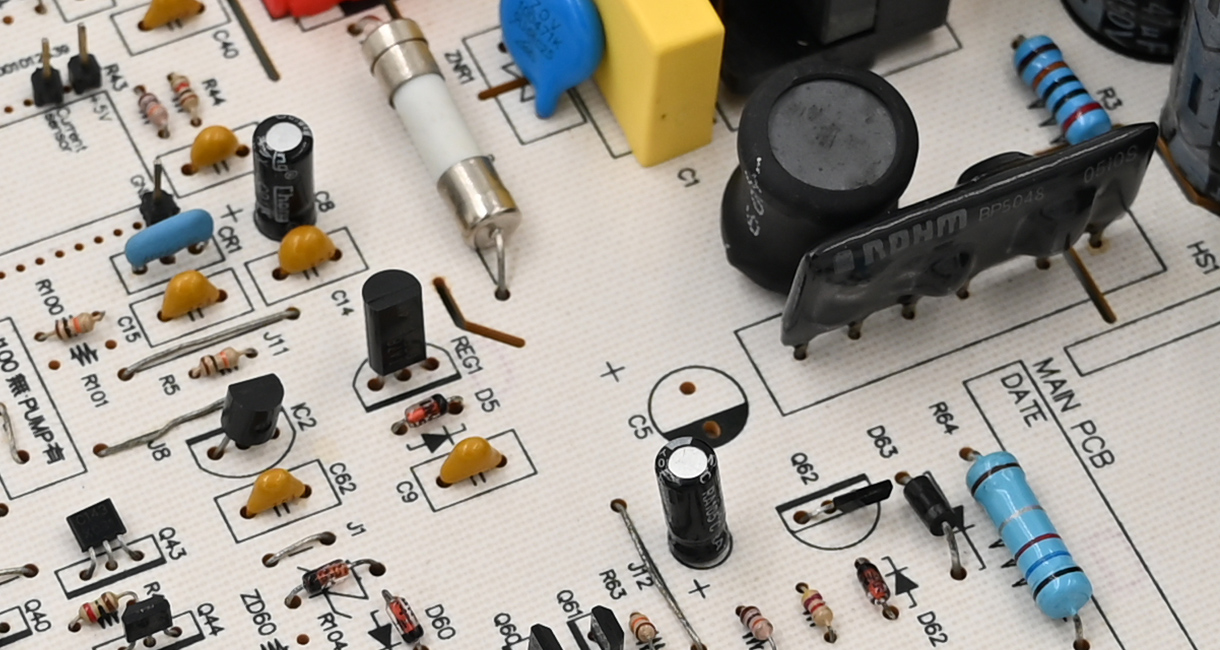

SMT & THT Assembly

Part Procurement

Chip Programming

PCBA Testing Service

Conformal Coating -

EMS Value-Added Service

3D Printing Prototype Service

Metal/Plastic Box Building Service

Wire Harness & Cable Assembly

Finished Product Assembly

Unixplore Electronics Co., Ltd.

About Us

2024-06-05

Manual soldering VS automated soldering in PCB assembly

During PCBA processing, soldering is an important step in connecting electronic components to the printed circuit board. Welding can be divided into two methods: manual welding and automated welding. Each method has its advantages and limitations. The choice depends on the project needs and budget.

2024-05-02

Raw material traceability and supply chain management in PCBA manufacturing

In PCBA manufacturing, raw material traceability and supply chain management are key aspects to ensure product quality, reliability and compliance. Here are some key considerations related to raw material traceability and supply chain management:

2024-04-18

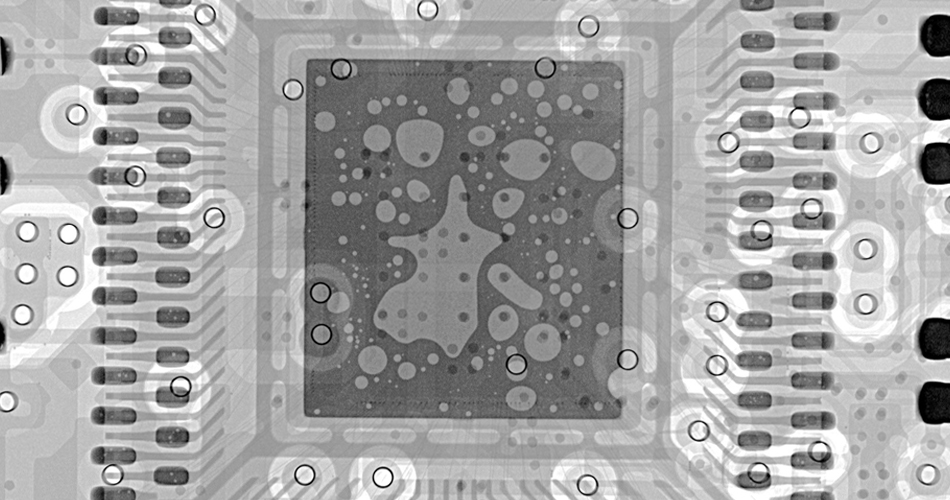

X-ray inspection and solder joint analysis in PCBA assembly

During the PCBA assembly process, X-ray inspection and solder joint analysis are two important quality control tools that help ensure the quality and reliability of solder joints. Here are the details on both:

2024-04-16

Testability and design specifications in PCBA design

In PCBA design, testability (Testability) and compliance with design specifications (Design for Manufacturability and Assembly, DFMA) are two key concepts that help ensure the production quality and test feasibility of the circuit board. Here are the details on both:

2024-01-15

Q: What is contract electronic manufacturing?

A: Contract Electronic Manufacturing (CEM) refers to the outsourcing of electronics manufacturing services to a third-party company. CEM companies provide a range of services including design, prototyping, testing, and assembly of electronic components and products. These services are typically used by Original Equipment Manufacturers (OEMs) who may not have the resources or expertise to manufacture their own products. CEM can be cost-effective and allow companies to focus on their core competencies while outsourcing non-core activities to specialized partners.

2024-01-09

A new base material for circuit board recycling: soluble when in water

With the continuous popularization of various types of electronic products in the information age, the production scale of printed circuit boards as component carriers is also expanding, and about 18 billion square meters of circuit boards produced around the world each year. And more and more new circuit boards are produced and used, which means that a large number of old circuit boards are scrapped and eliminated. Generally speaking, the circuit board will be processed and recovered.